-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

High Speed Drip Edge Roll Forming Machine

.png?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Drip edge is a roofing material component typically made of metal, such as aluminum or galvanized steel. It's a narrow strip of material that's installed along the edges of a roof, such as along the eaves and rakes (sloping edges). Here’s a breakdown of its purpose and advantages:

Application:

Eaves: Drip edge is installed along the eaves (the lower edges of the roof that overhang the walls of the building). It's positioned under the roofing material (such as shingles) and extends slightly outward. This placement helps direct water away from the fascia and prevents it from seeping into the underlying structure of the roof.

Rakes: Along the rakes (the sloped edges of the roof), the drip edge is placed over the roofing material. This helps prevent water from flowing back under the roof covering.

Purpose:

Water Management: The primary purpose of a drip edge is to manage water runoff efficiently. It helps direct water away from the fascia and prevents it from pooling or causing damage to the roof deck and underlying structure.

Protection: Drip edge protects the roof structure by preventing water intrusion and decay at the roof edges. It also helps keep out insects and small animals.

Advantages:

Prevents Rot and Damage: By directing water away from vulnerable areas like the fascia and roof deck, drip edge helps prevent rot, decay, and damage caused by water infiltration.

Enhances Roof Longevity: Installing drip edge can prolong the life of the roof by protecting it from water damage, which can lead to costly repairs or premature replacement.

Improves Appearance: Drip edge provides a neat, finished appearance to the roof edges, enhancing the overall aesthetics of the roofing system.

In summary, drip edge is a critical component of a roofing system, playing a key role in managing water runoff and protecting the roof structure. Its installation is recommended as part of a well-designed roofing system to ensure longevity and durability of the roof.

.jpg)

|

Raw Material

|

PPGI

|

|

Material Thickness: 0.46Mm

|

|

|

Machine Frame

|

20mm thick steel wall plate welding

|

|

Machine Structure

|

Vertical Arch Frame Structure

|

|

Material Of Rollers

|

GCr12 quenched

|

|

Forming stations

|

15 stations

|

|

Diameter of shafts

|

Φ50mm

|

|

Material of shafts

|

45# Steel Tampering Treatment, Prevent Deformed And Improve The Hardness

|

|

Forming speed

|

About 30m/min

|

|

Voltage

|

380v 50hz 3phase Or As local customer request

|

|

Transmission

|

Gear Transmission

|

|

Material Of Gear: 20 Crmnti

|

|

|

Work power

|

11 kw

|

|

Cutting blade material

|

Cr12Mov quenched treatment to improve hardness

|

|

Cutting type

|

Hydraulic servo cutting

|

Working Flow

.jpg)

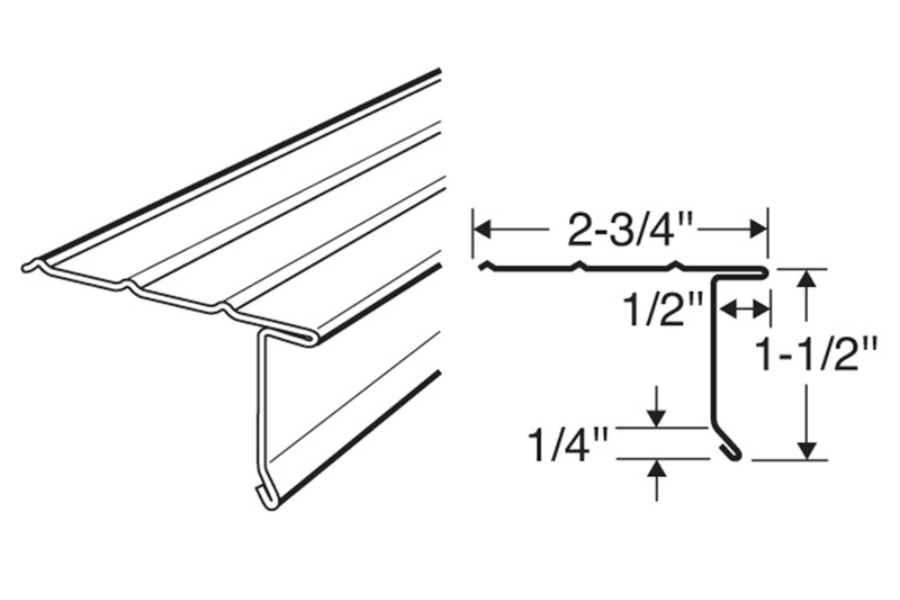

Profile Drawing

Finished Product

.jpg)

Machine Shows

.jpg)