-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Mexico Popular 100-35 Ceiling Roof Wall Sheet Roll Forming Machine

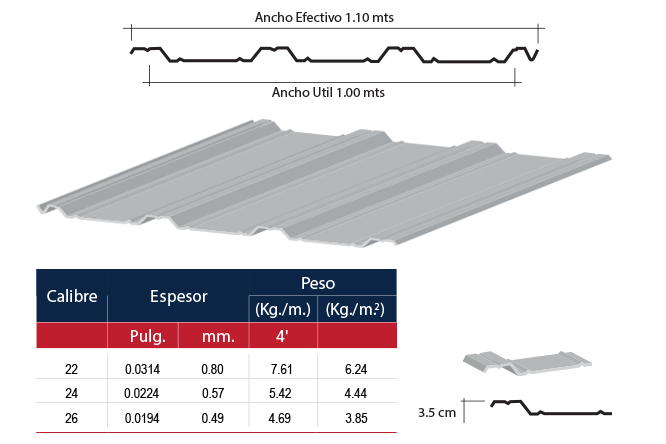

The term 100/35 roof panel refers to a profiled metal roofing panel with specific dimensions: 100 mm width between the ribs and 35 mm rib height. This design gives the panel strength and stability, making it ideal for both roofing and wall cladding applications.

The panel is typically made from galvanized steel or aluminum, both of which are known for their durability and corrosion resistance. The ribbed profile helps improve the panel’s load-bearing capacity and water runoff, making it an excellent choice for buildings exposed to the elements.

The RN-100/35 (RN 100) sheet is a Ribbed profile on a stationary rolling machine using the best quality steel rolls. Its geometric configuration is ideal since it has a double anti-siphon channel which provides excellent drainage capabilities. Due to its high structural resistance, it can be specified on industrial warehouse roofs where structural capacity is required, in addition to designing with low slopes (minimum slope of 6%).

In addition to being widely used on roofs, it is also recommended for use on facades due to its versatility and lightness in

installation.

It has an excellent drainage capacity due to its 3.50 cm camber and its exclusive design that involves the double anti-siphon channel.

Great structural resistance, ideal for the construction of high-specification industrial buildings.

Excellent structural capacity and drainage

It has a double anti-siphon channel.

|

Item NO |

Description |

Offered specification |

|

1.0 |

Roll forming machine |

|

|

1.1 |

Rolling speed |

10-12 meters/min(not include cutting time) |

|

1.2 |

Rolling thickness |

0.3mm-0.8mm |

|

1.3 |

Raw material |

Color painted coils, Aluminium, Zinc, Galvanized |

|

1.4 |

Main Motor |

5.5KW*2 |

|

1.5 |

Dimension |

About 11000×1600×1200(mm) |

|

1.6 |

Roller stations |

About 28 stations

|

|

1.7 |

Roller material |

45#forge steel, coated with chrome |

|

1.8 |

Shaft diameter |

Φ76mm |

|

1.9 |

Transmission |

By chain 1.2 inch |

|

1.10 |

Material of chain |

45# forged steel with frequency quenching, 12A |

|

1.11 |

Material of cutting |

Cr12Mov with quench HRC58-62° |

|

1.12 |

Tolerance |

10m+-1.5mm |

|

1.13 |

Hydraulic station |

4kw |

Machine List:

|

No |

Name |

quantity |

|

1 |

5 ton passive de-coiler |

1 set |

|

2 |

Main roll forming machine |

1 set |

|

3 |

Control box |

1 unit |

|

4 |

Hydraulic station |

1 unit |

|

5 |

Passive Output table |

2 units |

|

6 |

Mesh cover |

1 unit |

|

7 |

Spare part |

1 package |

Profile Drawing:

Sample pictures:

Application:

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)