-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

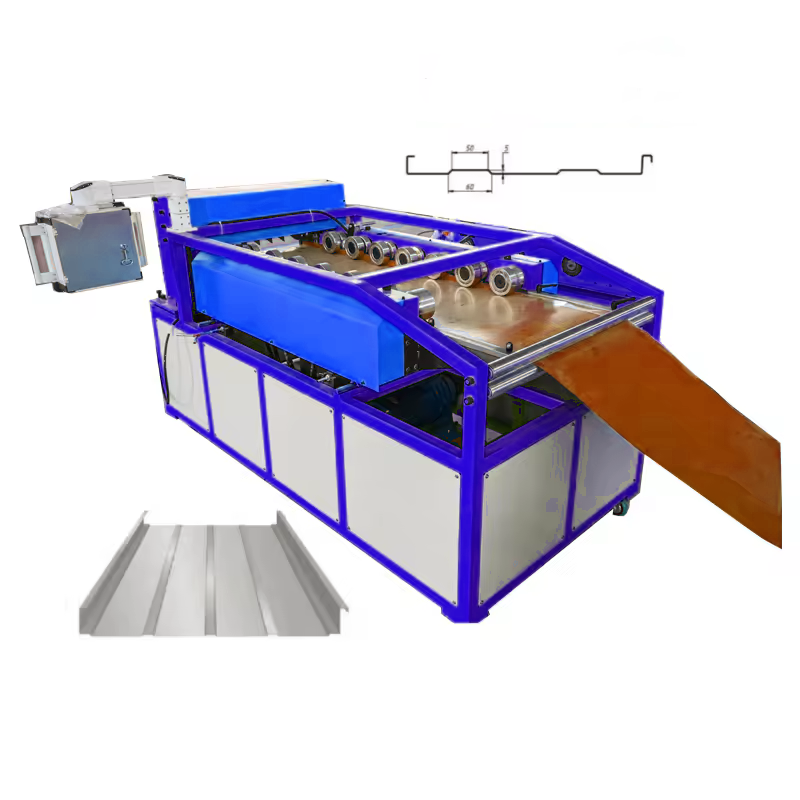

Portable Beam Standing Making Machine Metal Roof and Wall Panel Roll Forming Machine

A small metal roofing machine.

1.Formed Material:PPGI,GI,AI Thickness:0.3-0.8mm

2.Decoiler:Hydraulic automatic decoiler Manual decoiler(will give you as free)

3.Roller station:7 rows(As your requirement)

Diameter of shaft:80mm solid shaft

Material of rollers:45# steel, hard chrome plated on the surface

Machine body frame :Square tube welded with steel panel

Drive:Gear transmission

Dimension(L*W*H):about 2300*1500*1600(customize)

Weight:about 2.2T

4.Cutter:Automatic cr12mov material, no scratches, no deformation

5.Motor Power:3KW

Hydraulic system power:3KW

6.Voltage:380V 50Hz 3Phase or as your requirement

7.Control system:Electric Box

Language English(Support multiple languages)

PLC:Automatic production of the whole machine. Can set batch, length, quantity, etc.

8.Forming Speed:0-15m/min adjustable

Key Features and Benefits:

-

Mobility:

- Portable Design: These machines are designed to be easily transported to different job sites. They are typically mounted on trailers or fitted with wheels, allowing contractors to move them to wherever they are needed.

- On-Site Production: The ability to produce standing seam panels directly on-site eliminates the need for transportation of pre-formed panels, reducing costs and minimizing the risk of damage during transit.

-

Flexibility and Versatility:

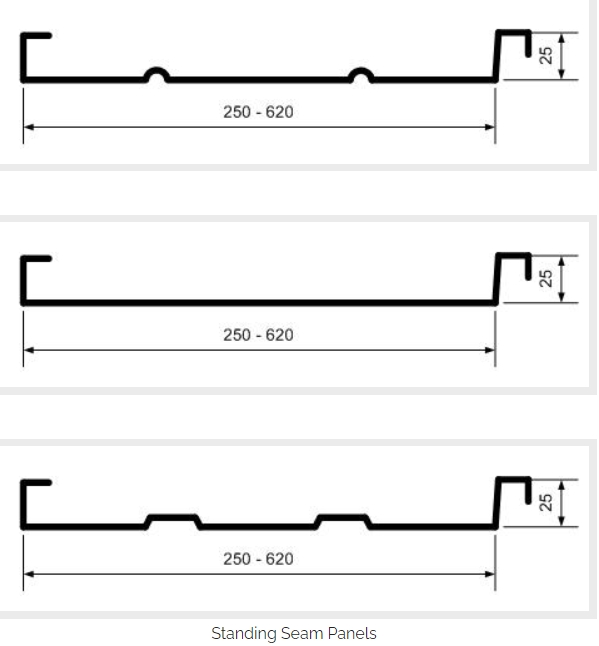

- Adjustable Profiles: Many portable standing seam roll forming machines can produce different profiles and panel widths, accommodating various architectural requirements.

- Material Compatibility: These machines are capable of working with a range of materials, including aluminum, galvanized steel, copper, and other metals commonly used in roofing.

- Custom Lengths: Since panels are formed on-site, they can be cut to the exact length required, reducing waste and ensuring a perfect fit for each roof.

-

Precision and Quality:

- Consistent Output: Despite their portability, these machines are engineered to produce high-quality, precise standing seam panels with consistent seam heights and tight tolerances.

- Durable Construction: Built to withstand the rigors of on-site work, these machines are made from heavy-duty materials and components, ensuring long-lasting performance.

-

Ease of Use:

- User-Friendly Controls: Most machines are equipped with intuitive controls, allowing operators to easily adjust settings and monitor production.

- Quick Setup: Designed for efficiency, portable roll forming machines can be set up and ready to produce panels in a short amount of time, maximizing productivity on the job site.

-

Applications:

- Residential and Commercial Roofing: These machines are used to produce standing seam panels for a wide variety of roofing projects, including residential homes, commercial buildings, and industrial facilities.

- Architectural Metalwork: Beyond roofing, the panels produced can be used for wall cladding, facades, and other architectural metalwork.

-

Cost Efficiency:

- Reduced Material Waste: By producing panels on-site to the exact required length, waste is minimized, leading to cost savings.

- Lower Labor Costs: With the machine on-site, the need for extensive manual labor is reduced, speeding up the installation process.

Considerations When Choosing a Portable Metal Roof Machine:

- Capacity: Ensure the machine can handle the thickness and type of metal you intend to use.

- Profile Options: Check if the machine can produce the specific standing seam profiles required for your projects.

- Portability: Consider the size, weight, and ease of transportation of the machine.

- Power Requirements: Be aware of the power source required (e.g., electric, hydraulic) and its availability on-site.

- Manufacturer Support: Look for machines from reputable manufacturers who offer technical support, training, and maintenance services.

Conclusion:

A portable standing seam roll forming is an essential tool for roofing contractors who need flexibility, precision, and efficiency on the job site. By allowing the production of high-quality standing seam panels directly where they are needed, these machines help to streamline the roofing process, reduce costs, and ensure a perfect fit for each project.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)