-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

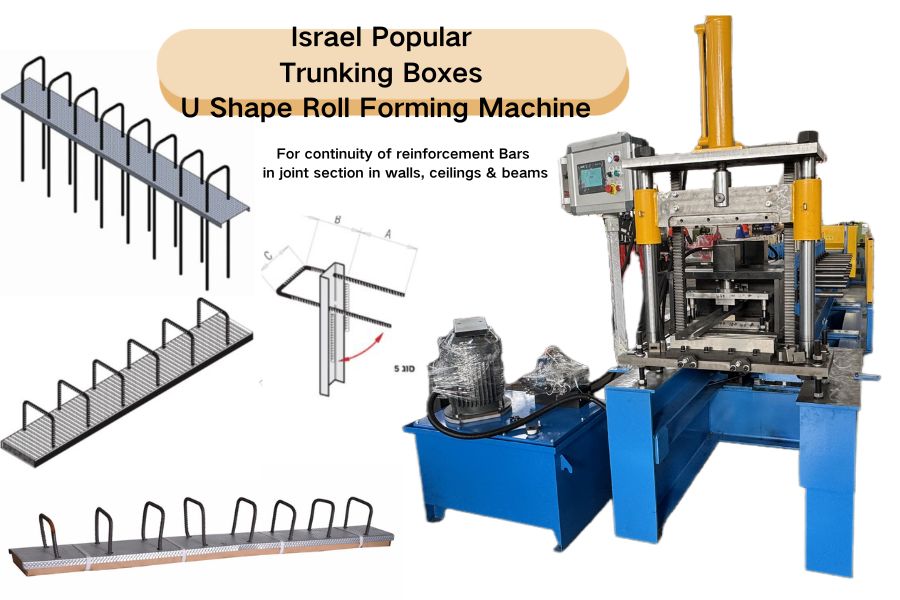

Trunking Boxes U Shape Roll Forming Machine

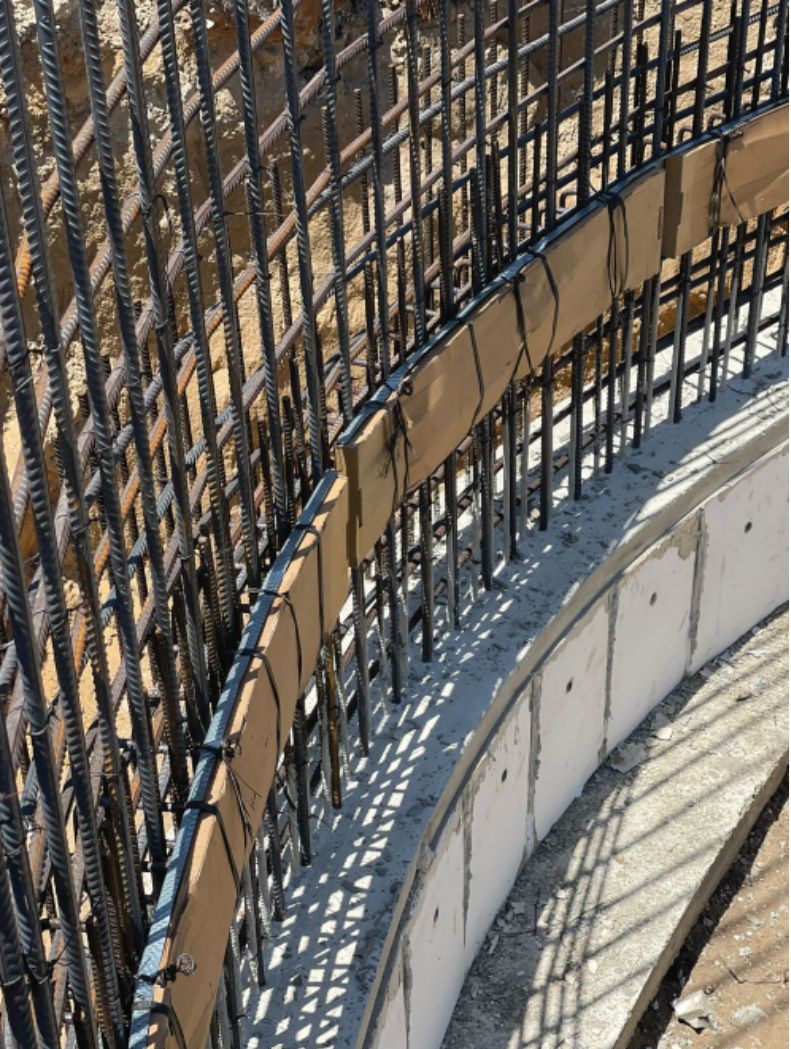

Continuous casting is a critical process in the metallurgical industry, enabling the production of high-quality metal products with improved efficiency and reduced waste. One of the key components that ensure the success of continuous casting is the trunking box. In recent years, Israel has emerged as a leader in the design and manufacturing of advanced trunking boxes, which are now widely used in steel plants and foundries worldwide.

This machine can produce multiple sizes U shapes, width 80-330mm, with embossing patterns.

Technical Data:

|

Items |

Specifications |

|

|

Material of coil |

Material Thickness |

0.3-0.8mm Galvanized coils |

|

Forming system |

Rolling Speed |

0-10 meters/minute |

|

|

Roller Stations |

About 9 stations forming |

|

|

Roller Material |

45# Steel |

|

|

Shaft Material |

45# Steel Diameter 75mm shaft

|

|

|

Main Motor Power |

4 KW, Hydraulic Motor 5.5KW |

|

Cutting system |

Material Of Cutting |

CR12 with quench treatment |

|

|

Hardness |

HRC58-62 |

|

|

Tolerance |

+-1.5mm |

|

Electrical control system |

Electric Source |

400V, 50HZ,3 phase, according to buyer’s request |

|

|

Control System |

PLC with touch screen |

|

|

Weight |

About 5 tons |

|

|

Way Of Drive |

1 inch single chain |

|

|

Size of machine |

Length 5000mm* Width 800mm* Height 1000m |

Machine List:

|

3 Tons Electric Decoiler |

1 set |

|

Embossing Machine |

1 set |

|

Main Roll Forming Machine |

1 set |

|

Hydraulic Punching Device |

1 set |

|

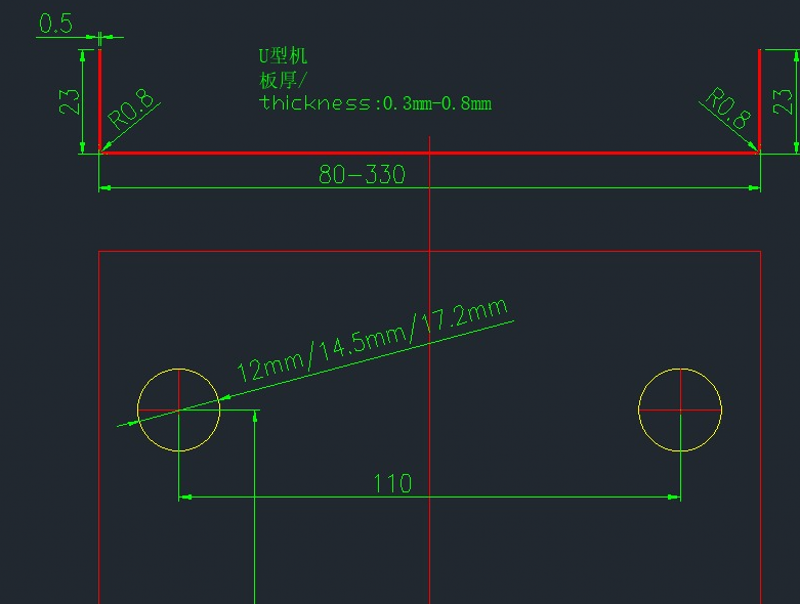

Hydraulic Punching Mould (12mm, 14.5mm, 17.2mm diameter) |

3 sets |

|

PLC Control Box |

1 unit |

|

Hydraulic Cutting Device |

1 unit |

|

6 Meters Passive Output Table |

1 unit |

|

Spare parts |

1 package |

|

Safety cover |

1 unit |

Profile Drawing:

Sample Pictures:

Application:

.jpg?x-oss-process=image/resize,w_100/quality,q_100)