-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

USA Galvanized Metal Steel Aluminum Hidden Joint Metafor Concealed Fastener Cladding Wall Siding Panel Roll Forming Machine

description1

Zipper closure

1/4 zip athletic pullovers for men. Stretchy, lightweight, fast-drying

fabric for superior performance.

REGULAR FIT - US standard sizes. An athletic fit that sits close to the body

for a wide range of motion, designed for optimal performance and all day

comfort.

FEATURES - Quarter zip closure;Thumbholes on long sleeves to keep them in

place during workout

Description

Specification

The advantages of using a Metal Wall Panel & Siding Roll Forming Machine include high efficiency, precision in producing consistent profiles, and the ability to manufacture panels in various lengths and profiles according to project requirements. These machines are commonly used in the construction industry to produce exterior cladding materials for buildings, including commercial, industrial, and residential structures.

Technical Data:

|

Item NO

|

Description |

Offered specification |

|

1.0

|

Roll forming machine

|

|

|

1.1

|

Rolling speed

|

10-12m/min

|

|

1.2

|

Rolling thickness

|

0.4-0.8mm

|

|

1.3

|

Raw material

|

Galvanized steel coils or PPGI

|

|

1.4

|

Main motor

|

7.5kw

|

|

1.5

|

Hydraulic motor

|

5.5kw

|

|

1.6

|

dimension

|

7500×700×1000(mm)

|

|

1.7

|

Roller stations

|

About 22 stations

|

|

1.8

|

Roller material

|

45#forge steel, coated with chrome

|

|

1.9

|

Shaft diameter

|

Φ70mm,material is 45# forge steel

|

|

1.10

|

Transmission

|

By chain 1 inch

|

|

1.11

|

Material of chain

|

45# forged steel with frequency quenching, 12A

|

|

1.12

|

Material of cutting

|

Cr12Mov with quench HRC58-62°

|

|

1.13

|

Tolerance

|

6m+-0.5mm

|

|

1.14

|

Frame

|

H type steel

|

|

1.15

|

Voltage

|

380v, 50hz, 3phases

|

Machine List:

|

No

|

Name

|

Quantity

|

|

1

|

5 ton hydraulic de-coiler

|

1 set

|

|

2

|

Main roll forming machine

|

1 set

|

|

3

|

Control box

|

1 unit

|

|

4

|

Hydraulic station

|

1 unit

|

|

5

|

Out tables

|

2 units

|

|

6

|

Safety cover

|

1 unit

|

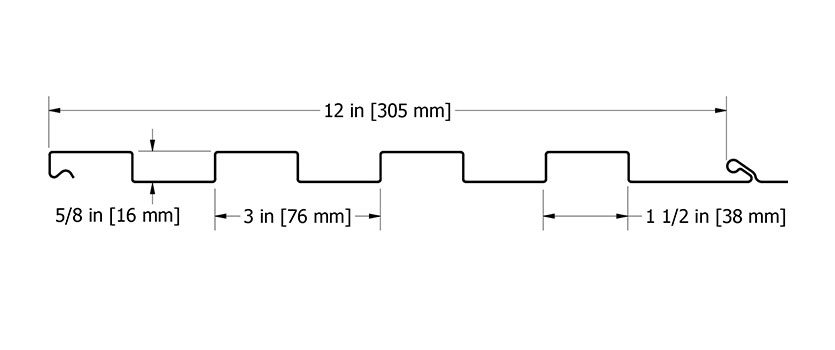

Profile Drawing:

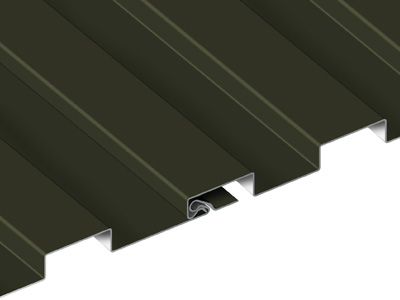

Sample Pictures:

Application:

.png?x-oss-process=image/resize,w_100/quality,q_100)