-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

12"-18" Clip Lock SSR Seam Standing Roof Panel Roll Forming Machine

Standing seam roof panels have been used on roofs of traditional and contemporary homes for more than a century and these standing seam metal roofing panels are commonly used on roofs of commercial businesses because of the roofing's outstanding durability.

These standing seam roof panels have area clean and graceful lines that have been an enduring favorite on a wide range ofarchitecture.

SL (Snap-Lock) 175 metal roofing panel is a snap locking standing seam metal roofing system that can be used for architectural and light structural applications. The snap lock metal roofing panel is secured with concealed clips and the snap locking standing seam metal roofing panel ribs snap lock securely together without the use of special tools. The snap lock metal roofing panels provide very good wind uplift resistance. SL 175 Snap Lock standing seam metal roofing panel can be specified as an accent feature or a total roof system for schools, shopping centers, banks, hotels, offices, and a variety of other applications.

SL150 is a snap lock standing seam roof panel that installs with concealed clips. The snap-lock standing seam roof panel

installation offers high levels of wind uplift protection and also allows these standing seam roof panels to float on the roof

deck, allowing for expansion and contraction with temperature extremes. Compared to Advantage-Lok standing seam metal roof panels, SL150 standing seam roof panel ribs have a more narrow, knife-edge profile that some customers prefer on their metal roofs. SL150 standing seam roof panel ribs snap securely in place over the clip to provide your roof maximum wind and weather resistance.

Technical Parameter:

|

Item NO

|

Description |

Offered specification |

|

1.0

|

Roll forming machine

|

|

|

1.1

|

Rolling speed

|

10-12 meters/min(not include cutting time)

|

|

1.2

|

Rolling thickness

|

0.3mm-0.8mm

|

|

1.3

|

Raw material

|

Color painted coils, Aluminium, Zinc, Galvanized

|

|

1.4

|

Main Motor

|

7.5KW

|

|

1.5

|

Dimension

|

About 1100×1600×1200(mm)

|

|

1.7

|

Roller stations

|

About 16 stations

|

|

1.8

|

Roller material

|

45#forge steel, coated with chrome

|

|

1.9

|

Shaft diameter

|

Φ76mm

|

|

1.10

|

Transmission

|

By chain 1.2 inch

|

|

1.11

|

Material of chain

|

45# forged steel with frequency quenching, 12A

|

|

1.12

|

Material of cutting

|

Cr12Mov with quench HRC58-62°

|

|

1.13

|

Tolerance

|

10m+-1.5mm

|

|

1.14

|

Hydraulic station

|

4kw

|

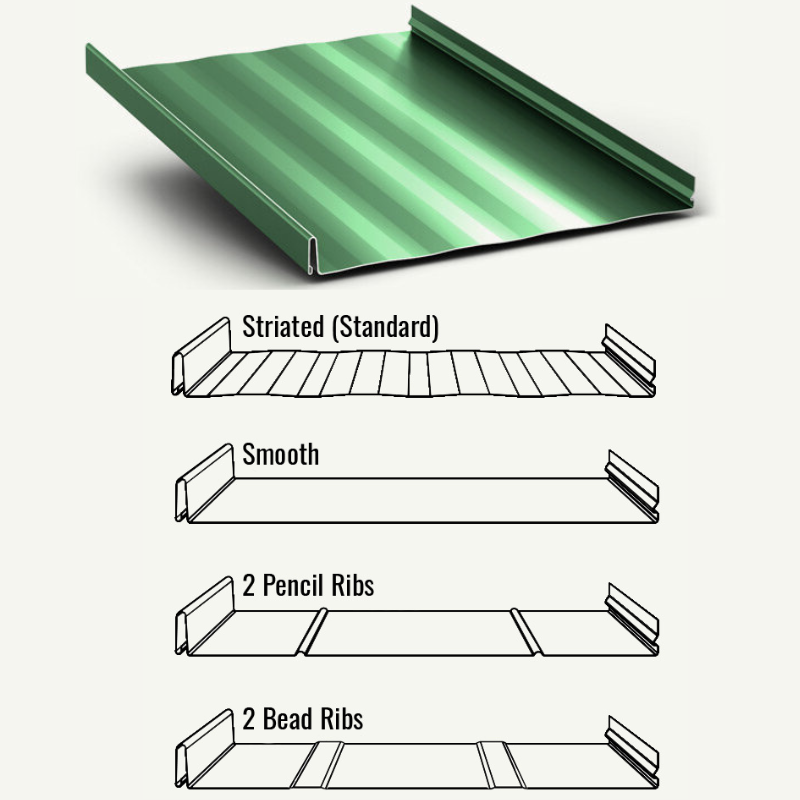

Profile Drawings:

Samples:

Application:

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)