-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Mexico Popular KR-18 KR-24 Portable Standing Seam Roof Roll Forming Machine

.jpg)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

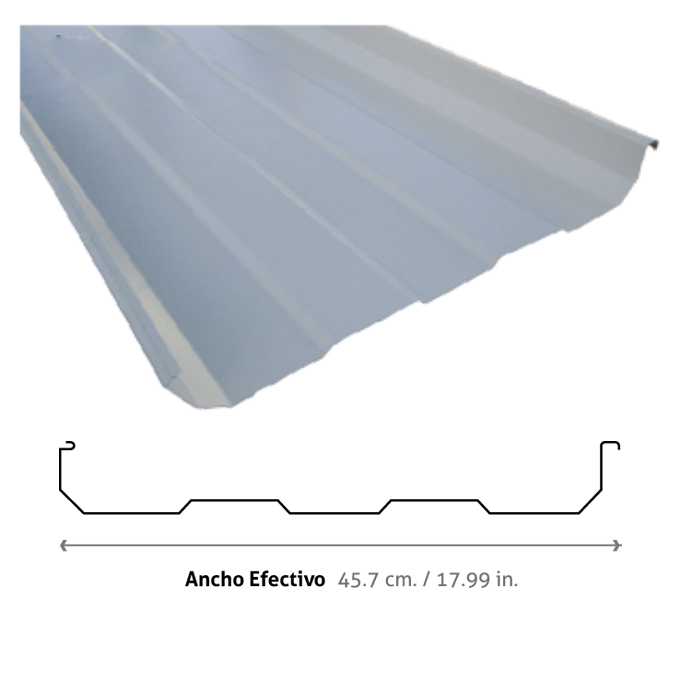

The KR-18(KR-24)profile is a ribbed and field-jointed SSR-type ( Standing Seaming Roof) roof system. Its fixing system is hidden using clips, which reduce the risk of possible leaks since it does not require drilling the Sheet.

It is a sheet manufactured on site, which means you can take this machine to produce on construction site, which is very popular in Mexico

Technical parameter

|

Item NO |

Description |

Unit\Type |

RF-RP |

|

1 |

Material Thickness |

mm |

0.3-0.8mm Galvanized, Galvalume, pre-painted steel |

|

2 |

Forming Speed |

m/min |

0-10 |

|

3 |

Roller stands |

stands |

7 |

|

4 |

Roller Material |

|

45# steel, coated with chrome, fire treated, HRC 58-62 |

|

5 |

Shaft diameter and materail |

|

Ф70, 45# steel, fire treated, HRC 58-62 |

|

6 |

Cutting device |

|

Post-cutting device |

|

7 |

Main Motor Power |

Kw |

5.5KW motor |

|

8 |

Hydraulic cutting Power |

Kw |

4KW |

|

9 |

Hydraulic pressure |

Mpa |

12 |

|

10 |

Power Supply |

|

According to client’s requiry |

|

11 |

Tolerance |

mm |

1.5 |

|

12 |

Material of cutting |

|

Cr12 |

|

13 |

Control system |

|

PLC with touch screen |

|

14 |

Main machine weight |

T |

2 Tons |

|

15 |

Width |

|

As profile |

|

16 |

Outer specification |

m |

4*0.9*1.5 |

|

17 |

Transmission Type |

|

1 inch chain drive |

2.Machine List

|

5 ton passive de-coiler |

1 set |

|

Hydraulic cutting device |

1 set |

|

Main roll forming machine |

1 set |

|

PLC Control box |

1 unit |

|

Hydraulic station |

1 unit |

|

2 meters passive table |

1 unit |

The KR-18 profile is a ribbed and field-jointed SSR-type roof system. Its fixing system is hidden using clips, which reduce the risk of possible leaks since it does not require drilling the Sheet.

Ancho Efectivo: 45.72 cm

Peralte: 6.35 cm.

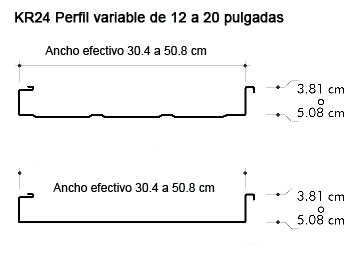

KR-24 Sheet – Ternium Hooked Ceilings

Cants from 3.8 cm to 5.1 cm (1.5″ – 2″) and Widths from 30.48 cm to 60.96 cm (12″ – 24″)

Finishes in Galvanized, Galvalume and Painted S

Lengths according to your needs.

L.A.B Monterrey, Nuevo León, Mexico, Federal District, Guadalajara, and Toluca (Delivery to the entire Republic).

Application

The price of Sussman's roll forming machines is a little higher than other suppliers'. Let me explain about our machines difference:

Sussman machine design: it is unit one, which means the control box and the hydraulic station are all put under the machine frame, when you get the machine, no need to assemble and connect the complicate cable of the machine, you only need to connect one main cable, then the machine is working. it saves more time and space.

Our display screen is touch screen, not text touch screen.

Sussman Processing technology: Sussman rollers is through grinding, quenched, chroming,finish machining,polishing,coated with chrome 0.05mm, all rollers are shiny, stronger and avoid rust.etc to make stronger, the roll forming machine is more robust and easier to use. The metal sheet produced by our machine is always flat and perfect profiles., because in the design and during the machining process, we always control the force for the metal sheet, it does not damage the sheet surface and comes out perfect profile. And we use the German application COPRA, to imitate the situation in 3D and ensure the perfect profile.

Sussman roll forming system: We will make the hand wheels at the feeding device to adjust feeding width, and we also make the wheels with the numbers then you know how to adjust right and left sides, also we made the rulers on the bedding, you can adjust the profile height and width according to the rulers.

Screw with numbers is to adjust material thickness easily, also with protecting cap also add laminating film device and felt to make the board flatter and smoother without scratches.

The machine is equipped with a detection switch device, in case of emergency, emergency alarm, stop operation.

-

DecolierDouble Heads Decoiler

A type decoiler

A type decoiler Manual Decoiler

Manual Decoiler Hydraulic Decoiler

Hydraulic Decoiler

-

StructureWall panel

Torri Structure

Torri Structure Cast Iron

Cast Iron

-

DriveChain

Gear

Gear Gearbox

Gearbox Couplings Gearbox

Couplings Gearbox

-

CoolingWater cooling

Fan cooling

Fan cooling

-

PunchingHydraulic punching

Hydraulic press

Hydraulic press Punching press

Punching press

-

CuttingHydraulic stop cutting

Servo Following Cutting

Servo Following Cutting Stop Saw cutting

Stop Saw cutting Fly saw cutting

Fly saw cutting

-

Out tableManual table

Simple pneumatic table

Simple pneumatic table Automatic stacker

Automatic stacker Magnetic stacker

Magnetic stacker

-

OtherCassette

Plastic film

Plastic film Fleece devce

Fleece devce Pre-cutting

Pre-cutting

.jpg?x-oss-process=image/resize,w_100/quality,q_100)