-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Beyond the Wood: The Rise of Metal Scaffolding Planks and Why They Are the Future

Sep 06, 2025

Beyond the Wood: The Rise of Metal Scaffolding Planks and Why They Are the Future

Introduction: The Evolution of a Work Platform

For centuries, timber was the only option for scaffolding decking. But as construction has evolved—embracing higher heights, faster timelines, and stricter safety protocols—the materials we use have had to evolve too. Enter the modern metal scaffolding plank: a product of precision engineering that is fundamentally changing how we think about worksite safety and efficiency. This blog explores the technical advantages of metal planks and makes the case for why they are becoming the new global standard.

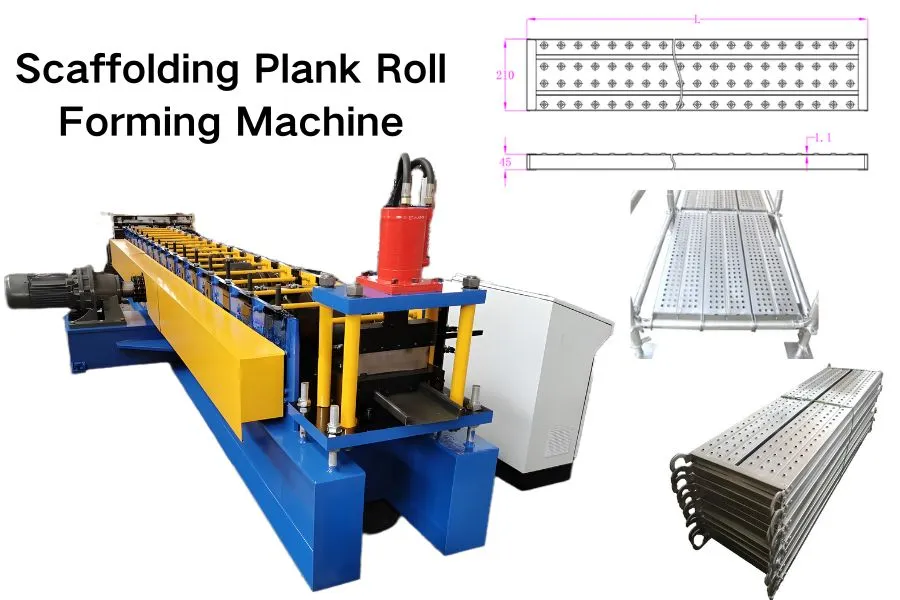

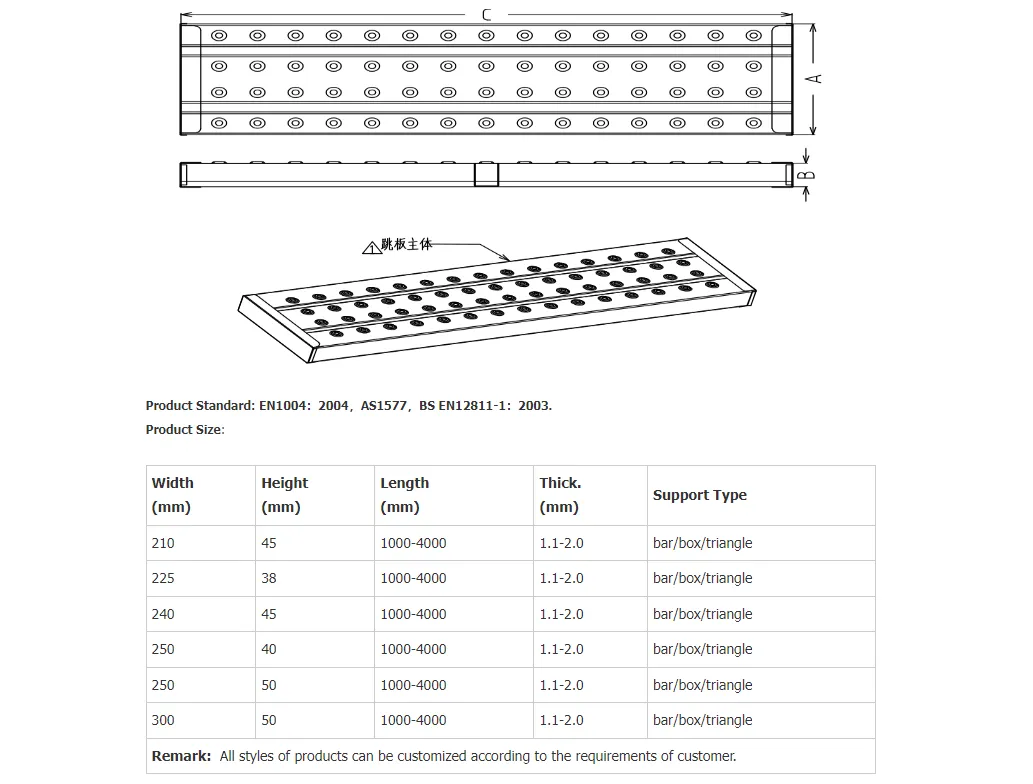

Chapter 1: The Engineering Behind the Strength: More Than Just a Sheet of Metal

Metal scaffolding planks are masterclasses in practical engineering. Their strength doesn't come from being thick and heavy, but from intelligent design.

-

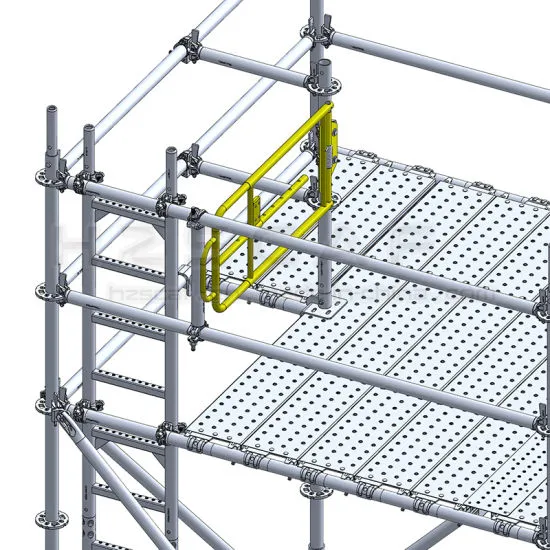

The Power of the Profile: Unlike a flat sheet, metal planks are roll-formed into specific profiles featuring longitudinal ribs or channels. This shape acts like a series of miniature I-beams, providing immense stiffness and strength-to-weight ratio. This means they can support heavy loads with minimal deflection (bending), creating a more stable and secure platform.

-

The Science of Slip Resistance: The perforated or expanded metal surface is a critical safety feature. It does more than just let debris and water fall through.

-

It provides a mechanical grip for boot soles that is effective in all weather conditions, far surpassing the variable grip of wood, especially when wet.

-

It reduces the surface area where mud, ice, or paint can build up, maintaining a safer surface for longer.

-

-

Material Science: Manufacturers use high-tensile strength steel (often S350GD or similar grade with a yield strength of 350 MPa) or corrosion-resistant aluminium alloys (like 6061 or 6082). These are often finished with hot-dip galvanization (a thick, bonded zinc coating for steel) or powder coating (for aluminium) to resist the harsh conditions of a job site.

Chapter 2: The Compelling Case for Metal Planks: A Total Cost of Ownership Perspective

While the initial purchase price of a metal plank is higher than a timber one, this is a classic case of false economy. The true cost must be calculated over the plank's entire lifespan.

-

Durability and Longevity: A well-maintained steel or aluminium plank can last for 10-15 years or more. A timber plank, even if carefully maintained, has a fraction of that lifespan. The constant cycle of purchasing, inspecting, and disposing of timber represents a significant and recurring cost.

-

Reduced Downtime and Inspection Time: Metal planks require less frequent and less intensive inspection. There's no need to check for splinters, rot, or warping. Their consistent performance means they are less likely to be failed in an inspection, keeping them on the job and reducing administrative overhead.

-

Labour and Logistics Savings: This is a major, often overlooked, factor.

-

Weight: An aluminium plank can weigh less than half of an equivalent timber plank. This means workers can handle them more easily and quickly, reducing fatigue and the risk of strain injuries.

-

Crane Time: Lighter planks mean more can be lifted in a single crane cycle, reducing expensive crane rental time on high-rise projects.

-

Transport: More planks can be loaded onto a truck, reducing transportation costs.

-

-

Fire Safety: Metal planks are non-combustible. This is a critical advantage on projects with hot work (welding, grinding) or in facilities with a high fire risk. They help mitigate a significant worksite hazard.

Chapter 3: Addressing Common Concerns and Misconceptions

-

"They are too expensive." As outlined above, the higher initial cost is an investment that pays for itself many times over through longevity, reduced labour costs, and eliminated replacement purchases.

-

"They are slippery." This is the opposite of the truth. The perforated metal surface offers superior, more reliable slip resistance than any other plank material, particularly in the wet conditions that make timber dangerously slick.

-

"You can't cut them to size on-site." While true, this is actually a benefit. It ensures the structural integrity of the plank is never compromised by an on-site modification. Custom lengths can be ordered from the manufacturer, and adjustable decking systems are available for odd-sized gaps.

Chapter 4: The Verdict: Building a Safer, More Efficient Future

The construction industry is increasingly defined by its focus on safety, efficiency, and sustainability. Metal scaffolding planks excel in all three areas:

-

Safety: They provide a stronger, more stable, and consistently slip-resistant platform, directly reducing the risk of falls, the leading cause of death in construction.

-

Efficiency: They save time and money every day through easier handling, faster installation, reduced equipment time, and less frequent inspections.

-

Sustainability: Their incredible longevity means far less material waste over time. At the end of their long life, both steel and aluminium are 100% recyclable.

.webp)

Conclusion: Making the Switch

The evidence is clear. Metal scaffolding planks are not just an alternative to wood; they are a superior successor. For any company serious about safeguarding its workers, improving its bottom line, and modernizing its operations, the transition to a metal decking system is one of the most impactful decisions it can make. It's time to leave the splinters, the rot, and the inconsistent performance of timber in the past and build the future on a platform of proven metal.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria