-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

The Silent Guardians of the Highway: A Deep Dive into W-Beam and Thrie-Beam Guardrails

Sep 06, 2025

The Silent Guardians of the Highway: A Deep Dive into W-Beam and Thrie-Beam Guardrails

Introduction: More Than Just a Strip of Metal

Every day, millions of motorists drive past them without a second thought. Yet, these corrugated steel ribbons lining our highways are among the most meticulously engineered and critically important safety features on the road. Highway guardrails, or safety barriers, are not meant to prevent accidents but to dramatically reduce their severity. They are designed to absorb catastrophic impact energy, gracefully redirect errant vehicles, and prevent them from crossing into oncoming traffic, rolling down embankments, or striking fixed objects like bridge piers.

Among the various types, two profiles stand out as the global workhorses of roadside safety: the W-Beam (2-wave) and the Thrie-Beam (3-wave). Understanding their design, function, and application is key to appreciating the complex science that keeps us safe. This blog serves as your ultimate guide to these unsung heroes of the infrastructure world.

The Physics of Survival: How Guardrails Work

A guardrail is not a rigid wall. Its purpose is to be a "forgiving" barrier. In a crash, the system is designed to perform a life-saving ballet:

-

Capture: The vehicle's bumper or side makes contact with the face of the guardrail.

-

Redirect: The rail and its support posts deform and buckle in a highly controlled, predictable manner. This process converts the vehicle's kinetic energy into deformation energy and friction, slowing it down gradually instead of abruptly.

-

Contain: The system must be strong enough to prevent the vehicle from penetrating through it, snagging on a post, or vaulting over the top, guiding it to a safer stop.

This concept of controlled deceleration is the cornerstone of modern roadside safety design.

The Workhorse: W-Beam (2-Wave) Guardrail

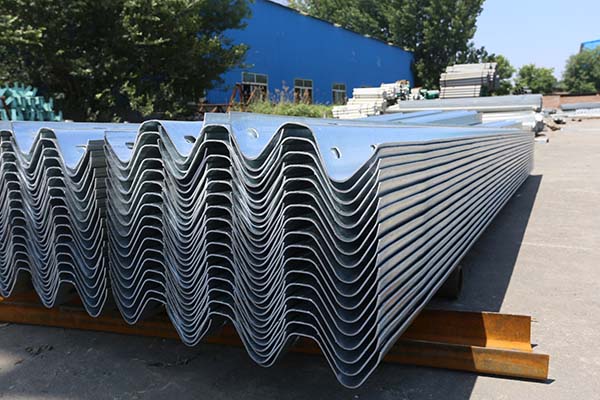

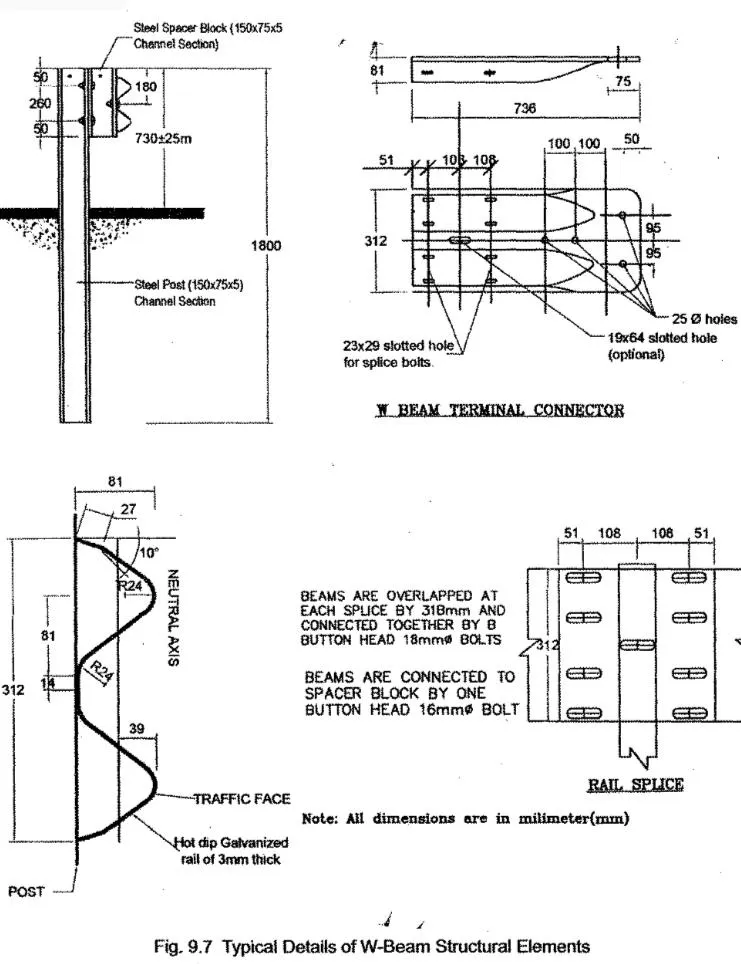

The W-Beam is the most common guardrail system found on roads worldwide. Its name comes from its distinctive profile, which features two back-to-back, rounded "W" shapes, creating a two-rib corrugated section.

-

Profile & Construction: Typically fabricated from galvanized steel sheet, the standard W-beam is 12-gauge (approx. 2.66 mm thick) with a 312 mm (12.25 inches) depth. The corrugation is not for aesthetics; it dramatically increases the beam's stiffness and strength along its length, much like the flanges on an I-beam.

-

Function: It is classified as a semi-rigid barrier. It is designed to deflect (bend and move) significantly upon impact. This deflection is a feature, not a flaw, as it is the primary mechanism for absorbing energy.

-

Ideal Applications: The W-beam is the default, cost-effective solution for the vast majority of highway scenarios.

-

Medians on divided highways to prevent cross-over collisions.

-

Roadside applications where the terrain behind the rail is relatively flat and clear (the "clear zone"), allowing for the necessary deflection distance.

-

Areas with predominantly passenger vehicle and light truck traffic.

-

-

Limitations: Its energy-absorption capacity has limits. It is less effective at containing heavier vehicles (like semi-trucks and buses) or managing high-angle, high-speed impacts. In these extreme cases, a vehicle may "pocket" the rail (digging into it), break through, or roll over.

The Heavy-Duty Protector: Thrie-Beam (3-Wave) Guardrail

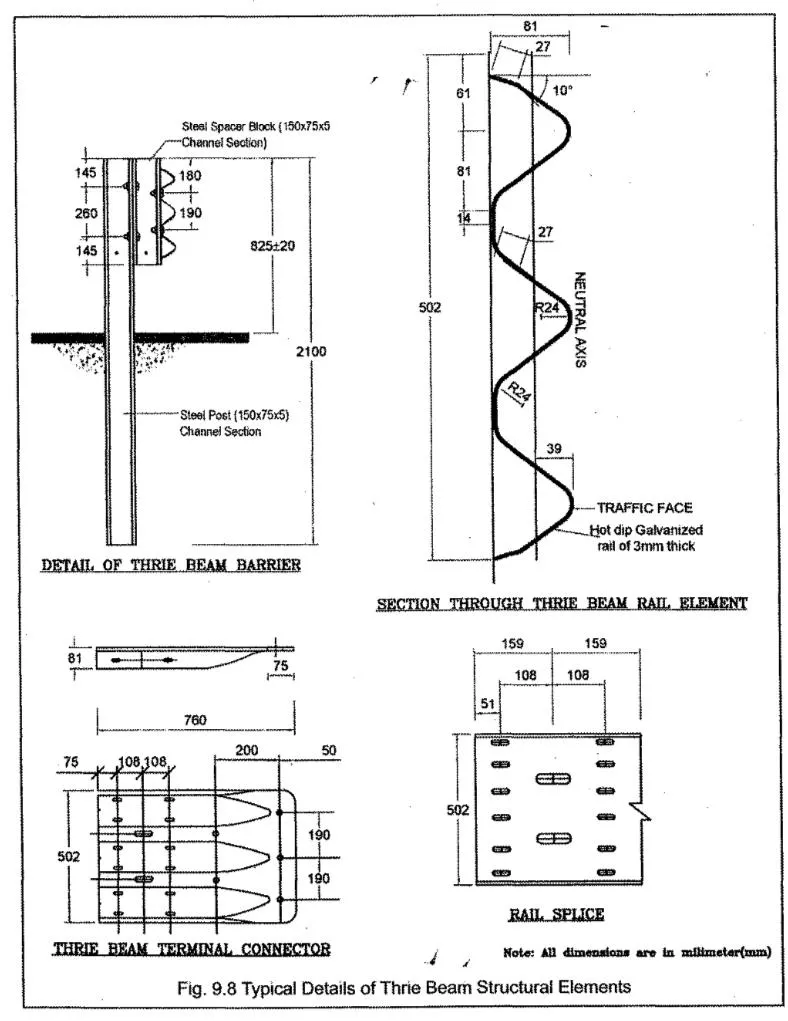

The Thrie-Beam is the big brother of the W-beam. Its name comes from "triple," referring to its three-rib, deeper corrugated profile.

-

Profile & Construction: Also made from galvanized steel, the Thrie-Beam is a larger, heavier-gauge section. It is often 10-gauge (approx. 3.43 mm thick) with a 483 mm (19 inches) depth. The extra metal and the third corrugation make it substantially stronger, stiffer, and more durable.

-

Function: Like the W-beam, it is a semi-rigid barrier, but it operates at a higher performance level. It is designed to deflect less than a W-beam upon impact, providing a higher level of containment and resistance.

-

Ideal Applications: The Thrie-Beam is the specialist, deployed in high-risk, high-consequence areas where a W-beam is insufficient.

-

High-volume, high-speed freeways and interstates.

-

Locations with a limited "clear zone" where less deflection is critical. This includes areas near steep drops, deep water, bridges, or rocky outcrops.

-

Sharp curves where impact angles are more severe and the risk of a vehicle striking the barrier is higher.

-

Specifically for containing heavier vehicles like tractor-trailers, buses, and tankers.

-

-

Limitations: The primary drawback is cost. It requires more raw material, heavier steel posts, and more robust foundations, making it a significantly more expensive investment.

Side-by-Side Comparison: Choosing the Right Tool for the Job

| Feature | W-Beam (2-Wave) | Thrie-Beam (3-Wave) |

|---|---|---|

| Profile | Two corrugations / ribs | Three corrugations / ribs |

| Strength & Stiffness | Good (Semi-Rigid) | Excellent (Semi-Rigid to Rigid) |

| Deflection | Higher | Lower |

| Containment Level | Standard passenger vehicles, light trucks | Heavy trucks, buses, high-energy impacts |

| Cost | Lower | Higher (more steel, heavier posts) |

| Primary Application | Standard highways, medians, clear zones | High-risk areas, limited clear zones, sharp curves |

Conclusion: A System of Calculated Protection

The choice between a 2-wave and a 3-wave guardrail is never arbitrary. It is a calculated engineering decision based on a rigorous risk assessment that considers traffic volume, speed, vehicle mix, and the roadside environment. While the versatile W-beam efficiently handles most scenarios, the robust Thrie-Beam is the critical upgrade for our most dangerous roads. Together, these two systems form an adaptable, life-saving network—a testament to the unseen engineering that protects us on every journey.

If you are interested in, welcome to inquiry!

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria