-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

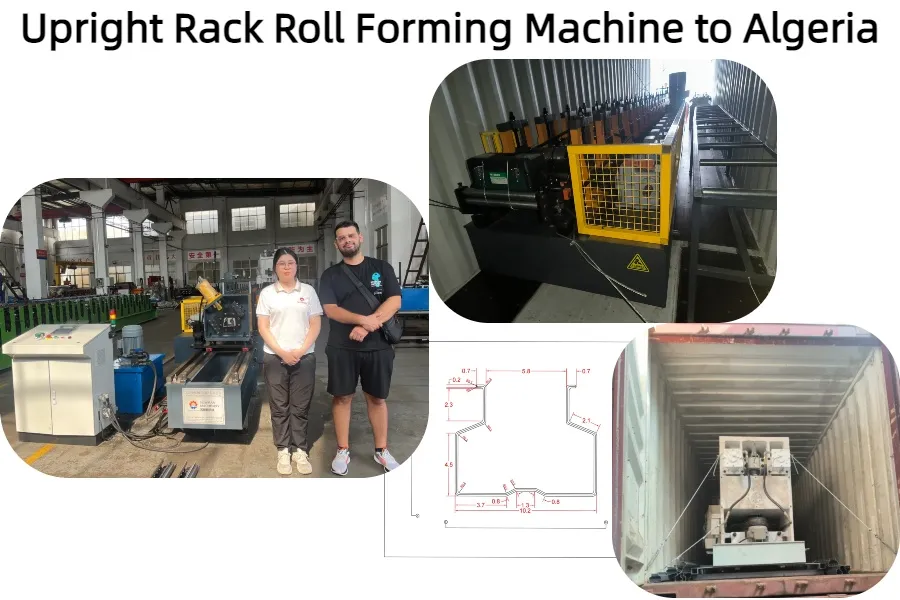

Upright Rack Roll Forming Machine Shipped to Algeria

Sep 19, 2025

On September 15, a major milestone was reached at our factory as a state-of-the-art upright rack roll forming machine was carefully loaded into a shipping container, marking the beginning of its journey to Shanghai Port. From there, the machine will continue its route to Algeria, where it will become an integral part of a customer’s production line. This shipment demonstrates our factory’s growing role in supplying advanced roll forming equipment to global markets, while also reflecting the increasing demand for efficient and durable storage solutions worldwide.

The machine in question is not a simple piece of equipment—it is a full production line specifically designed to manufacture upright racks, a core component in warehouse racking systems. Upright racks, also known as shelving uprights or rack columns, form the vertical backbone of pallet racking structures, allowing heavy-duty shelving systems to support large loads while maximizing vertical storage space. With the continued expansion of logistics, e-commerce, and industrial warehousing, the demand for high-quality rack manufacturing equipment has been rising sharply.

Technical Strengths of the Machine

This particular upright rack roll forming line is designed to process steel sheets with a thickness of 2.5mm, ensuring the production of strong, durable uprights capable of withstanding heavy loads. The integration of an 80-ton punching press allows for precise hole punching along the length of the rack uprights, enabling the adjustable connection of beams and other racking components.

In addition, the machine is equipped with a fly cutting system that ensures continuous operation without the need to stop the line for cutting. This significantly improves production efficiency. Combined with a maximum speed of 15 meters per minute, the line provides a powerful balance between speed, accuracy, and material handling. Such features are particularly important for customers in Algeria, where industrial storage and logistics infrastructure are undergoing rapid growth.

Customer’s Perspective

The Algerian customer who purchased this machine is deeply involved in the warehousing and shelving industry. By investing in a complete production line, the customer aims to expand production capacity, improve product consistency, and reduce reliance on imported racking products. Local manufacturing not only reduces costs but also provides flexibility in meeting market-specific requirements, such as customized dimensions or hole patterns.

The decision to purchase from our factory reflects the trust built through previous communications, technical discussions, and demonstrations of our expertise in roll forming machinery. Our engineering team worked closely with the customer to ensure the machine meets their exact needs, from punching designs to material thickness capabilities.

Broader Market Implications

The shipment of this upright rack roll forming machine also reflects broader market trends. Across North Africa, countries such as Algeria, Morocco, and Tunisia are experiencing steady growth in manufacturing, construction, and logistics. As companies invest in modern supply chains and storage facilities, the demand for reliable racking systems has never been higher. By acquiring advanced production lines, local manufacturers can strengthen their position in the market and even compete regionally.

Commitment to Quality and Service

Before shipment, our technical team conducted a series of rigorous tests to ensure all components—forming rollers, punching dies, and cutting mechanisms—were in perfect working condition. The customer will also receive detailed installation guidance, along with after-sales service support, ensuring that the line will operate smoothly once it arrives in Algeria.

This successful shipment once again highlights our factory’s commitment to providing high-quality roll forming solutions worldwide. From design and production to logistics and after-sales service, we are dedicated to helping our customers achieve efficiency, reliability, and competitiveness.

As the machine makes its way to Algeria, it symbolizes not only the expansion of our global presence but also the strengthening of industrial cooperation between China and North Africa. With every shipment, we continue to build long-term partnerships that support global industrial development.

Related News

October 26, 2016

The Most Successful Engineering Contractor