-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Australia Metal Fencing System Roll Forming Machines – Manufacturing Excellence for Superior Perimeter Solutions

Jul 12, 2025

Australia Metal Fencing System Roll Forming Machines – Manufacturing Excellence for Superior Perimeter Solutions

Introduction

Australia's fencing industry relies on precision-engineered metal fencing systems that combine durability, security, and aesthetic appeal. At the heart of this manufacturing process are advanced roll forming machines that produce high-quality fence posts, rails, and panels to meet strict Australian standards. These automated systems enable cost-effective production of fencing components designed to withstand the country's harsh climate conditions, from tropical humidity to outback heat.

In this comprehensive guide, we'll explore:

✔ How roll forming machines revolutionize fence manufacturing

✔ Key components of Australian metal fencing systems

✔ Material specifications for different environments

✔ Compliance with Australian fencing standards

Roll Forming Machines: The Backbone of Fence Production

Machine Capabilities

-

High-speed production: 15-30 meters per minute output

-

Precision tolerances: ±0.2mm accuracy for consistent profiles

-

Multi-station forming: 12-18 roller stations for complex shapes

-

Automated cutting: Hydraulic or servo systems for clean edges

Fence Component Production

-

Fence Posts

-

C-channel or square profiles

-

Pre-punched holes for rail attachment

-

Galvanized or powder-coated finishes

-

-

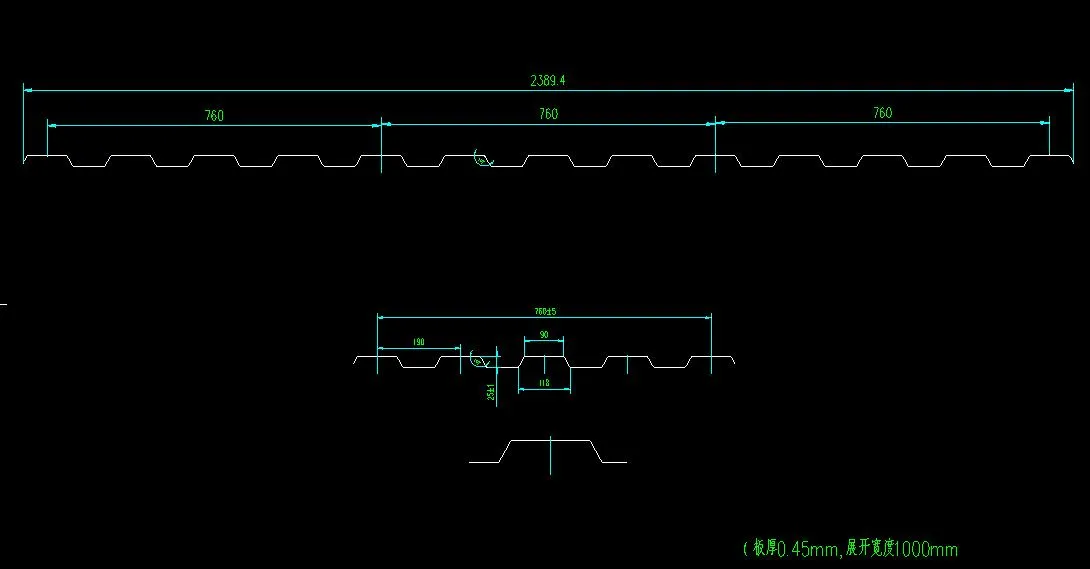

Fence Rails

-

Z-shape or rectangular hollow sections

-

Anti-sag designs for long spans

-

Compatible with various panel types

-

-

Fence Panels

-

Privacy, semi-private, or ornamental designs

-

Laser-cut patterns available

-

Colorbond® or custom color options

-

Australian Metal Fencing System Components

1. Fence Posts

-

Materials: Galvanized steel (1.5-3mm thickness), aluminum

-

Standard sizes: 65x65mm to 100x100mm

-

Features:

-

Ground-set depth: Minimum 600mm for stability

-

Optional concrete footings for high-wind areas

-

Pre-galvanized to AS 1397 standards

-

2. Fence Rails

-

Horizontal members: Typically 2-3 rails per panel

-

Profile types:

-

Z-section (most common)

-

C-section for heavy-duty applications

-

Decorative scalloped designs

-

3. Fence Panels

-

Panel types:

-

Privacy: Solid or louvered designs

-

Semi-private: Slatted or perforated patterns

-

Ornamental: Laser-cut decorative elements

-

-

Standard heights: 1.2m to 2.4m

Material Specifications for Australian Conditions

Environment Recommended Material Protective Treatment Expected Lifespan Coastal Aluminium 6063-T6 Powder coating 25+ years Bushfire zones Galvanized steel Colorbond® Steel 20+ years Urban residential Pre-painted steel Zincalume® coating 15-20 years Rural/agricultural Heavy-duty galvanized Additional paint system 30+ years Compliance with Australian Standards

-

AS 1725: Farm fencing requirements

-

AS 1926.1: Pool fencing regulations

-

AS 1397: Continuous hot-dip metallic coatings

-

BASIX: Thermal performance in NSW

ConclusionModern roll forming machines enable the production of high-performance metal fencing systems that meet Australia's diverse needs. From coastal residences to rural properties, these precision-manufactured components offer long-lasting protection and aesthetic appeal while complying with strict local standards.

Any interested in the Fence Post, fence track, fence panel machine, welcome to inquiry!

-

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria