-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Egyptian customers come to visit

Mar 13, 2024

Egyptian customers come to discuss shelf panel equipment. We start communicating on this line since May, 2023.

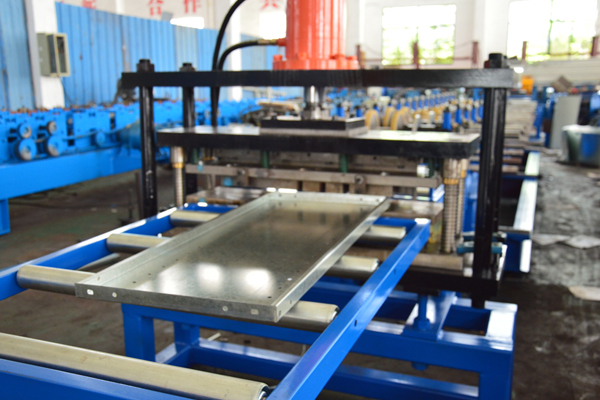

The customer wants to confirm the final details and drawings before placing an order. The attached picture is of shelf panel machine.

A "shelf panel machine" typically refers to equipment or machinery used in the manufacturing of shelf panels. These machines are commonly utilized in industries such as retail, warehousing, logistics, and manufacturing to produce panels used for shelves, racks, storage systems, and displays. Here's an overview of the components and processes involved in a typical shelf panel machine:

Roll Forming Machine: The primary component of a shelf panel machine is usually a roll forming machine. This machine takes flat metal coils or sheets and processes them through a series of rollers to create the desired shape and profile for the shelf panels. Roll forming allows for high-speed, continuous production of uniform panels with consistent dimensions.

Material Feeding System: Raw materials, such as steel coils or sheets, are fed into the roll forming machine using a material feeding system. This system ensures a steady supply of material to the machine for uninterrupted production.

Cutting System: Once the shelf panel profile is formed, a cutting system is employed to cut the panels to the desired length. This system may use techniques such as shearing, punching, or sawing to achieve precise cuts according to the specifications of the panels.

Embossing or Perforation: Some shelf panel machines may include additional features for embossing patterns or perforating holes in the panels. These enhancements can improve the functionality or aesthetics of the panels and allow for customization according to specific requirements.

Bending or Folding: In certain cases, shelf panel machines may incorporate bending or folding mechanisms to shape the panels into specific configurations, such as angled shelves or corner units.

Control System: Modern shelf panel machines often feature computerized control systems to monitor and adjust various parameters during production. These control systems help ensure accuracy, efficiency, and consistency in panel manufacturing.

Please check this links to get this machine detailed informatin, thank you

https://www.sussmanmachinery.com/shop/racking-shelf-box-roll-forming-machine👈

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria

.jpg?x-oss-process=image/resize,w_100/quality,q_100)