-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

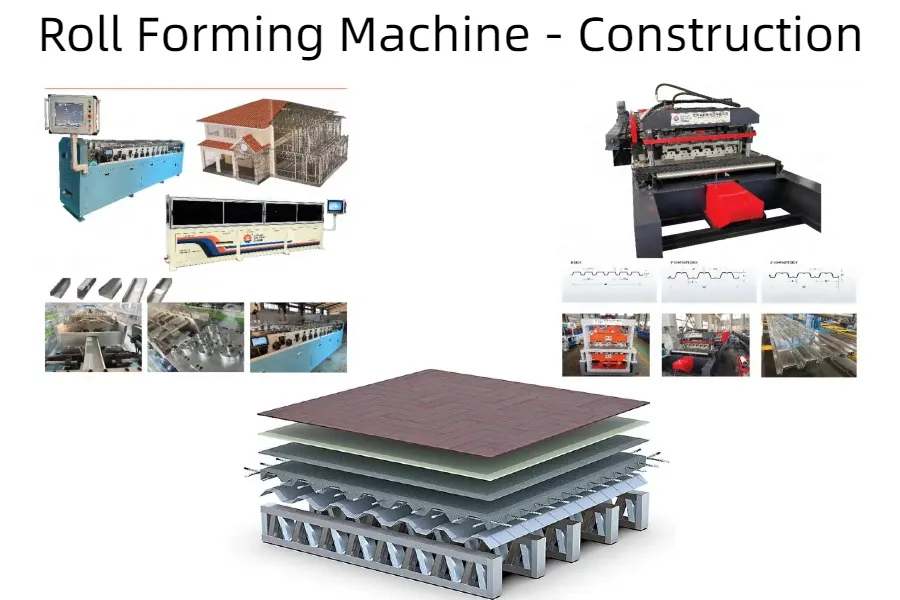

From Coil to Construction – How Roll Forming Machines Build Homes and Warehouses

Aug 20, 2025

When a steel coil enters a cold roll forming machine, it begins a journey that ends in a finished building. This journey is central to modern residential housing and warehouse construction, where prefabrication and precision are key. Understanding which machines are used and how their products are installed reveals the power of this technology.

Building the Skeleton

Every structure begins with a skeleton.

-

For residential housing, Light Gauge Steel Framing Machines create the vertical studs, horizontal tracks, and roof trusses. These members are labeled and cut to exact dimensions. On-site, builders assemble them with screws, similar to assembling a steel puzzle, ensuring both speed and accuracy.

-

For warehouses, C/Z Purlin Machines are crucial. The purlins they produce carry the load of the roof and wall panels across wide spans. Installation involves bolting them directly onto the primary steel frame, forming the backbone of the enclosure.

Covering the Structure

Once the skeleton is ready, the building must be covered and protected.

-

Roof Panel Machines produce corrugated or trapezoidal sheets that are fastened with screws and washers. In warehouses, these panels cover large surfaces quickly.

-

Standing Seam Machines provide a premium solution. Their concealed-fastener panels lock together using a seaming machine, ensuring long-lasting waterproofing—perfect for both elegant residential roofs and expansive warehouses.

-

Wall Panel Machines supply either single-skin cladding or insulated sandwich panels. These are mounted vertically or horizontally onto purlins, giving the building its finished look and thermal performance.

Adding Strength with Floors

In multi-story houses and mezzanine-equipped warehouses, Floor Deck Roll Forming Machines come into play. They create ribbed sheets laid over steel beams. Once concrete is poured, the result is a composite floor slab that can withstand heavy loads while reducing material usage.

Completing the Details

No building is complete without functional details:

-

Gutter and Downspout Machines provide drainage systems that manage rainwater. Gutters are installed along roof edges, and downpipes are connected vertically to channel water safely to the ground.

-

Ridge Cap and Flashing Machines supply finishing elements that seal joints and enhance appearance.

-

Stud and Track Machines help in building residential interiors, producing partitions that support drywall and insulation.

Installation Advantages

The installation of roll formed products is designed to be quick and reliable. Profiles come cut to length, sometimes with pre-punched holes, minimizing adjustments on-site. Workers use bolts, screws, and simple hand tools to connect elements. For standing seam roofs, seaming equipment ensures secure locks. The result is faster construction with reduced labor costs.

Why Roll Forming Machines Matter

For residential builders, these machines provide lightweight, energy-efficient solutions that meet modern housing standards. For warehouse developers, they deliver large-span, cost-effective structures that can be built in record time. Both benefit from the consistency, durability, and versatility that cold roll forming machines provide.

Conclusion

From the first steel coil to the completed building, cold roll forming machines drive the process of modern construction. They produce the beams, the panels, the flooring, and even the finishing details. For houses, they enable safe and stylish homes. For warehouses, they ensure durable and efficient storage spaces. In both cases, the machines turn raw material into architecture—quickly, precisely, and economically.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria