-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

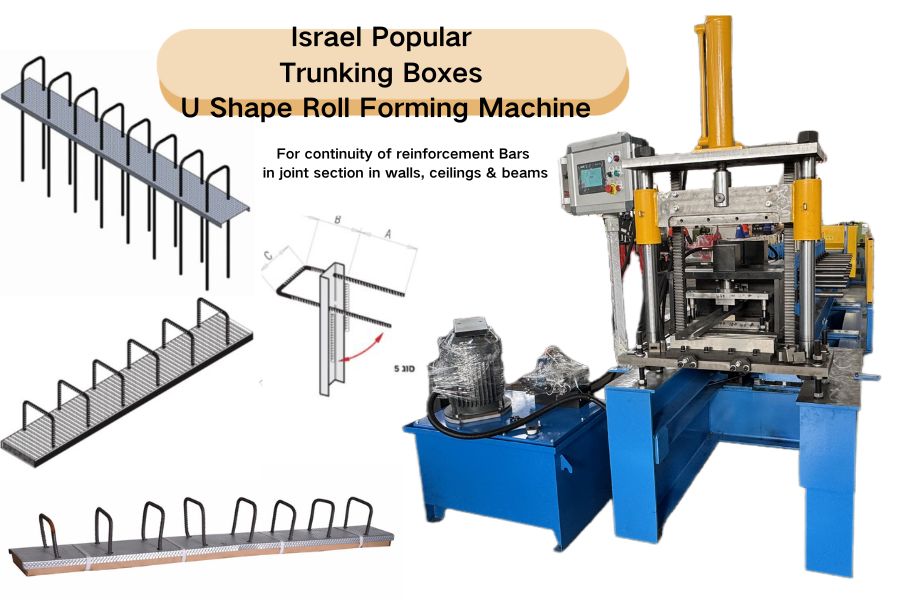

How Israeli Trunking Boxes are Enhancing Continuous Casting Efficiency and Quality

Mar 10, 2025

How Israeli Trunking Boxes are Enhancing Continuous Casting Efficiency and Quality

In the world of metallurgy, continuous casting is a game-changer. It allows for the production of metal products with superior quality and consistency. At the heart of this process lies the trunking box, a component that has seen significant advancements thanks to Israeli engineering. In this blog, we’ll dive deeper into how Israeli trunking boxes are enhancing the efficiency and quality of continuous casting processes.

The Continuous Casting Process: A Brief Overview

Continuous casting involves pouring molten metal into a mold, where it solidifies into a continuous strand. This strand is then cut into desired lengths for further processing. The trunking box plays a pivotal role in this process by acting as an intermediary reservoir that ensures a steady flow of molten metal into the mold.

Challenges in Continuous Casting

Despite its advantages, continuous casting comes with its own set of challenges:

-

Flow Irregularities: Inconsistent flow can lead to defects in the final product.

-

Temperature Fluctuations: Molten metal must remain at a specific temperature to prevent premature solidification.

-

Impurities: Slag and other impurities can compromise the quality of the metal.

Israeli trunking boxes address these challenges with innovative solutions.

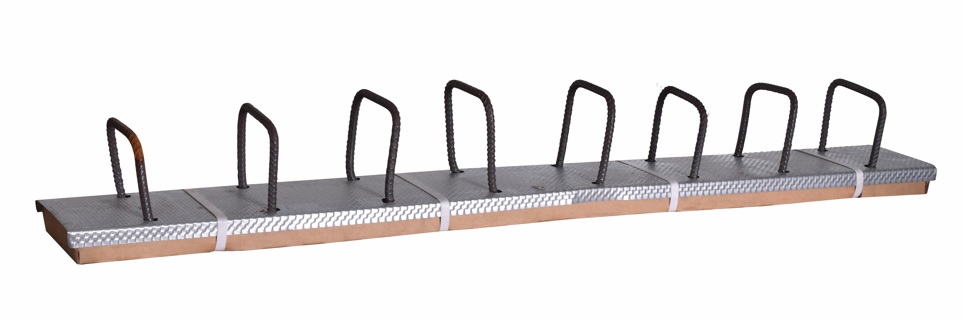

Key Features of Israeli Trunking Boxes

-

Precision Flow Control: Israeli trunking boxes are designed with advanced flow control mechanisms that ensure a consistent and uniform flow of molten metal. This reduces the risk of defects and improves the overall quality of the cast product.

-

Thermal Management: Israeli engineers have developed trunking boxes with superior thermal insulation properties. These boxes maintain the optimal temperature of the molten metal, preventing temperature fluctuations that could affect the casting process.

-

Slag Trapping Systems: Israeli trunking boxes incorporate advanced slag trapping systems that remove impurities from the molten metal. This results in cleaner, higher-quality metal products.

-

Durability and Longevity: Made from high-performance materials, Israeli trunking boxes are built to withstand the harsh conditions of continuous casting. This reduces downtime and maintenance costs.

Case Study: Israeli Trunking Boxes in Action

A leading steel manufacturer in Europe recently switched to Israeli trunking boxes for their continuous casting operations. The results were remarkable:

-

Product Quality: The company reported a 20% improvement in the quality of their steel billets.

-

Efficiency: The casting process became 15% more efficient, thanks to the precise flow control and thermal management features of the Israeli trunking boxes.

-

Cost Savings: Reduced maintenance and longer lifespans of the trunking boxes led to significant cost savings.

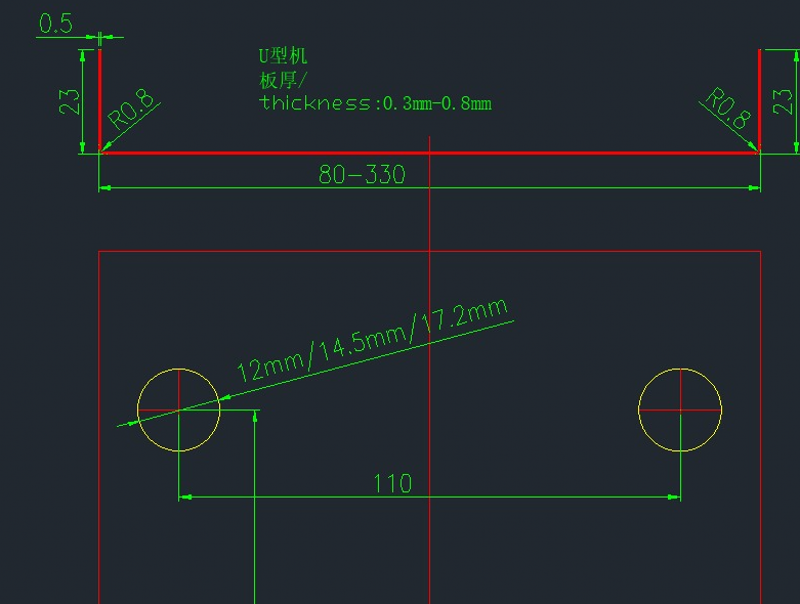

- 80-300mm width adjustable

Future Trends in Trunking Box Technology

Israeli companies are continuously pushing the boundaries of trunking box technology. Some of the trends to watch out for include:

-

AI and Machine Learning: Integrating AI to predict and optimize casting parameters in real-time.

-

Eco-Friendly Designs: Developing trunking boxes that further reduce energy consumption and environmental impact.

-

Modular Systems: Creating modular trunking boxes that can be easily upgraded or reconfigured for different casting applications.

Conclusion

Israeli trunking boxes are at the forefront of continuous casting technology, offering solutions that enhance efficiency, quality, and sustainability. By addressing the key challenges of the continuous casting process, these innovative components are helping manufacturers around the world achieve new levels of performance. As technology continues to evolve, Israeli trunking boxes will undoubtedly play a central role in shaping the future of metallurgy.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria