-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

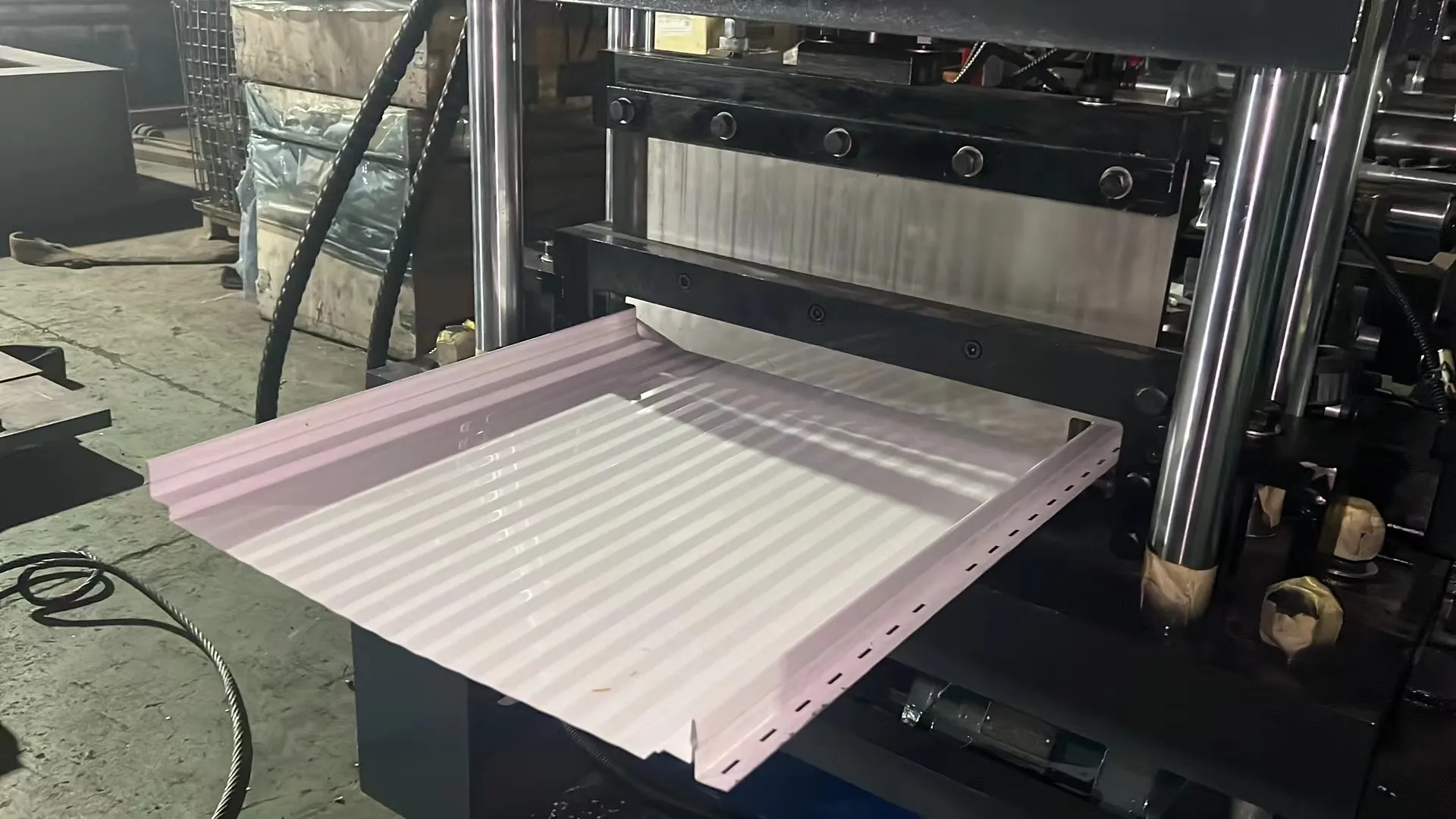

Nail Strip Western Seam

Aug 18, 2025

What Is a Nail Strip Standing Seam?

A nail strip standing seam (also called fastener flange standing seam) is a type of standing seam metal roofing profile that’s designed for easier and faster installation compared to traditional standing seam systems.

Nail strip, also known as nail flange or fastener flange, is a standing seam system with panel seams heights for either 1” or 1 ½ “. The panels are fastened directly to the deck through the male leg. Once the panel is secure, the female leg of the panel snaps over which hides the fasteners. Unlike Snap Lock, there are no clips used in this type of standing seam.

🔹 Key Features

-

Fastener-free look: The screws/nails are hidden beneath the seams, giving a clean, modern appearance.

-

Simpler installation: Since there are no separate clips, panels can be installed more quickly.

-

Low to medium slope use: Typically recommended for residential roofs with slopes of ≥3:12 (sometimes ≥2:12 depending on manufacturer).

-

Panel width: Commonly 12", 14", or 16".

Seam height: Usually 1" to 1.5" tall.

🔹 Pros

-

Cost-effective compared to clip-fastened standing seam.

-

Faster installation = lower labor cost.

-

Sleek, concealed fastener finish.

🔹 Cons

-

Less thermal movement tolerance: Since panels are fixed through the nail flange, expansion and contraction are more restricted than clip systems, making them less ideal for very long panel runs.

-

Typically not recommended for very low slopes (<2:12) or large commercial projects.

Deciding Between Standing Seam Panel Types

As we mentioned at the beginning of the article, Nail Strip is an entry level standing seam roof that is often installed by DIY roofers while Snap Lock systems are the more standard standing seam system. Though there are some cost savings with Nail Strip, you have to consider if the small price difference is really worth it.

If you want the roof with the best performance, Snap Lock is superior to Nail Strip. The majority of the roofing industry would agree Snap Lock is a better system with a much better long term value. It’s best to use Nail Strip panels when money and time are major concerns. However, there are some circumstances where a Nail Strip roof can be a better fit.

We can do without hole and with punched hole

🔹 Key Components

Decoiler – holds and feeds the raw metal coil.

Hydrualic pre-punching and cutting-- Punching the side holes and no need to change cutter blade

Roll forming stations – rollers gradually form standing seam profile.

Hydraulic cutting unit – cuts panels to desired length automatically.

Control system (PLC + HMI) – allows setting of panel length, quantity, etc.

Run-out table – collects finished panels.

🔹 Panel Specifications (typical ranges)

-

Material: Galvanized steel, Galvalume, aluminum, copper, zinc.

-

Thickness: 0.4–0.8 mm (24–26 gauge common for roofing).

-

Panel width: 300 mm – 500 mm (12"–20"), depending on tooling.

-

Seam height: 25–38 mm (1"–1.5").

-

Nail flange: Pre-punched slots or holes for fasteners

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria

.webp?x-oss-process=image/resize,w_100/quality,q_100)