-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Taper Roof Sheet Roll Forming Machine – The Ultimate Manufacturing Solution for Modern Roofing

Apr 01, 2025

Taper Roof Sheet Roll Forming Machine – The Ultimate Manufacturing Solution for Modern Roofing

Introduction

The roofing industry has evolved significantly with the introduction of taper roof sheet roll forming machines, which have revolutionized how we produce high-quality, durable roofing sheets. These machines manufacture tapered roof panels that are widely used in industrial, commercial, and agricultural buildings due to their sloped design for water drainage, strength, and cost-effectiveness.

In this blog, we will explore:

✔ What is a taper roof sheet roll forming machine?

✔ Key features and benefits

✔ Applications of taper roof sheets

✔ Why businesses should invest in this technology

What is a Taper Roof Sheet Roll Forming Machine?

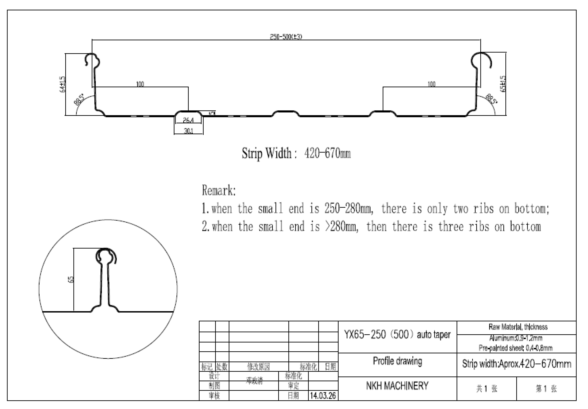

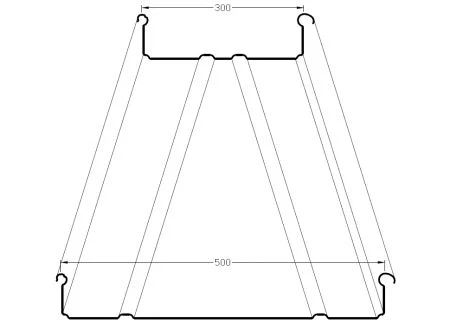

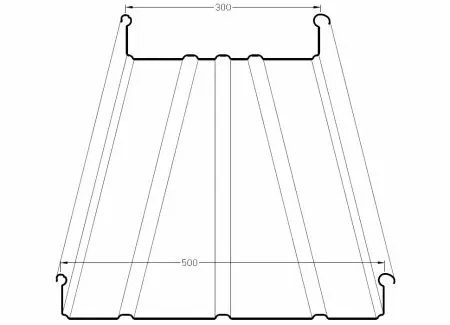

A taper roof sheet roll forming machine is an automated production line that transforms metal coils (steel, aluminum, or galvanized steel) into tapered roof panels with precise dimensions. These machines use a series of rollers to gradually shape the metal into the desired profile, ensuring uniformity and structural integrity.

Key Features of Taper Roof Sheet Roll Forming Machines

-

High-Speed Production

-

Capable of producing 0-10 meters per minute, significantly faster than manual fabrication.

-

Reduces labor costs and increases efficiency.

-

-

Precision Engineering

-

Computer-controlled (CNC) for consistent thickness and shape.

-

Adjustable rollers for different taper angles and sheet widths.

-

-

Material Flexibility

-

Works with galvanized steel, aluminum, and pre-painted coils.

-

Supports various thicknesses (0.3mm to 1.2mm).

-

-

Low Maintenance & Long Lifespan

-

Heavy-duty construction with wear-resistant rollers.

-

Minimal downtime due to easy-to-replace parts.

-

-

Customizable Profiles

-

Can produce different rib patterns (e.g., trapezoidal, corrugated).

-

Tailored for specific architectural needs.

-

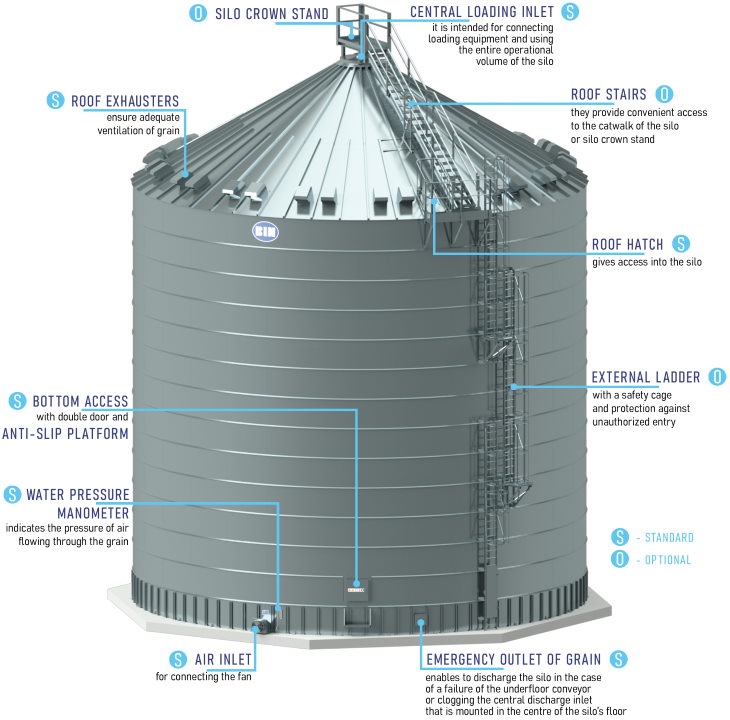

Applications of Taper Roof Sheets

Taper roof sheets are used in a variety of structures due to their sloped design, durability, and weather resistance.

1. Industrial & Warehouse Roofing

✔ Large-span coverage with fewer supports needed.

✔ Superior water drainage prevents leaks.

2. Commercial Buildings

✔ Sleek, modern appearance for shopping malls and offices.

✔ Fire-resistant and low-maintenance.

3. Agricultural & Poultry Sheds

✔ Corrosion-resistant (ideal for humid environments).

✔ Ventilation-friendly designs available.

4. Residential Roofing

✔ Lightweight yet strong (reduces structural load).

✔ Energy-efficient (reflects sunlight to keep interiors cool).

Why Invest in a Taper Roof Sheet Roll Forming Machine?

✅ Cost-Effective Production – Lower labor and material waste.

✅ On-Demand Manufacturing – Produce sheets as needed.

✅ High Profit Margins – Sell custom roofing sheets to contractors.

✅ Future-Proof Business – Growing demand for metal roofing.

Conclusion

Taper roof sheet roll forming machines are a game-changer for the roofing industry, offering speed, precision, and versatility in sheet metal production. Whether you're a manufacturer, contractor, or business owner, investing in this technology can boost efficiency and profitability.

If you are interested in, welcome to inquiry!

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria