-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

The Role of Sigma Purlins in Modern Structural Engineering

Jul 17, 2024

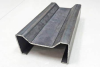

In the realm of structural engineering, Sigma purlins have emerged as a versatile and reliable component for supporting roofs and walls in various types of buildings. Characterized by their distinctive 'Σ'-shaped profile, these purlins offer numerous benefits that make them suitable for a wide range of applications. This article delves into the technical aspects of Sigma purlins, their benefits, and their role in contemporary construction projects.

Technical Aspects

Sigma purlins are fabricated from high-quality galvanized steel or aluminum, which provides excellent resistance to corrosion and environmental factors. The 'Σ' shape of these purlins is designed to optimize structural performance, with flanges and webs that contribute to their overall strength. The profile of a Sigma purlin ensures efficient load distribution, reducing the risk of deformation under heavy loads. This design also allows for the integration of additional components, such as insulation and cladding, without compromising the structural integrity of the building.

Benefits

The primary benefit of Sigma purlins lies in their superior strength-to-weight ratio. This property allows for the construction of buildings that are both strong and lightweight, minimizing the load on the foundation and other supporting structures. The 'Σ' shape provides enhanced resistance to buckling and lateral displacement, ensuring the stability of the roof or wall system. Additionally, Sigma purlins are highly versatile and can be cut and fabricated to fit specific design requirements, making them ideal for customized construction projects.

Another significant advantage of Sigma purlins is their ease of installation. The standardized dimensions and shapes of these purlins facilitate quick and efficient assembly, reducing construction time and labor costs. Furthermore, the use of Sigma purlins can lead to cost savings in materials, as their high strength allows for longer spans and fewer supports compared to traditional purlin shapes.

Applications

Sigma purlins are used in a variety of building types, including industrial, commercial, and agricultural structures. In industrial applications, they provide robust support for the roofs of factories, warehouses, and distribution centers, where large open spaces are crucial for operational efficiency. Commercial buildings, such as shopping malls, office buildings, and sports arenas, benefit from the flexibility and strength of Sigma purlins, enabling architects to design spacious interiors with fewer support columns.

In the agricultural sector, Sigma purlins are used in the construction of barns, storage facilities, and greenhouses. Their ability to withstand heavy loads and harsh environmental conditions makes them an ideal choice for agricultural buildings that require reliable and durable roofing solutions. Additionally, Sigma purlins are gaining popularity in residential construction, particularly in modern designs that emphasize open floor plans and large window openings.

Conclusion

Sigma purlins play a crucial role in modern structural engineering, offering a combination of strength, versatility, and ease of installation. Their unique 'Σ'-shaped profile provides several advantages over traditional purlin shapes, making them a preferred choice for a wide range of construction projects. As the demand for efficient and sustainable building solutions continues to grow, Sigma purlins are expected to become even more integral to the construction industry, contributing to the development of stronger and more resilient structures.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria

.jpg?x-oss-process=image/resize,w_100/quality,q_100)