-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

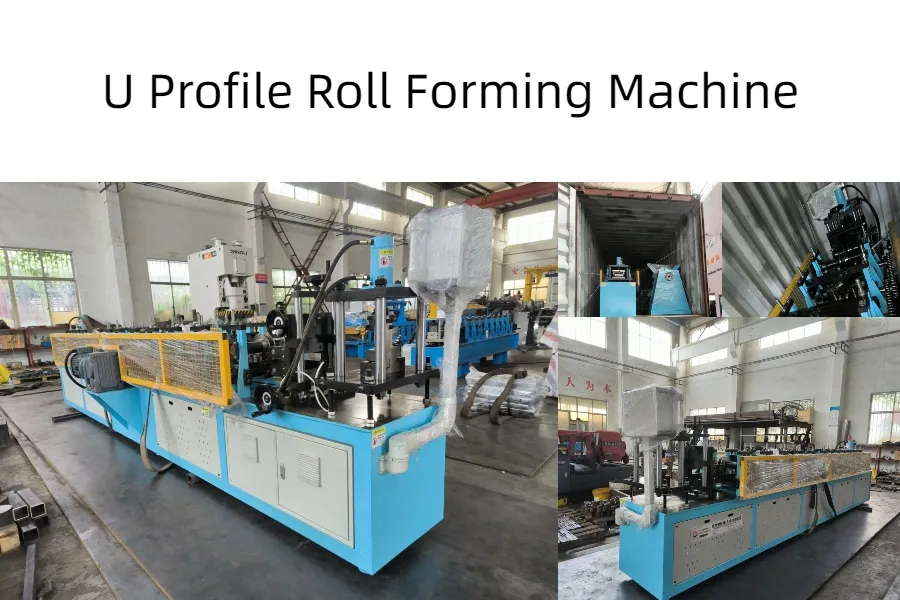

U Profile Roll Forming Machine Shipped to Mexico: Flexible Sizing and Hydraulic Punching Capabilities

Jul 12, 2025

On July 11, a significant shipment was prepared for delivery from our factory to the Shanghai Port, marking yet another successful export to the Latin American market. A U profile roll forming machine, designed to produce high-quality and customizable U-shaped metal profiles, was carefully loaded into a shipping container and is now en route to Mexico. This machine represents a combination of advanced engineering, flexibility, and operational efficiency, tailored to meet the dynamic demands of the Mexican construction and industrial sectors.

A Machine Designed for Versatility

What makes this U profile roll forming machine stand out is its capability to produce U profiles in multiple dimensions. The machine is engineered to adapt to various size requirements, allowing the user to change between different U profile sizes with precision. This is especially beneficial for customers involved in manufacturing projects that require different specifications for support structures, channels, or framing elements.

The flexibility in sizing helps eliminate the need to purchase multiple machines or undergo extensive manual reconfiguration. Instead, the machine is designed for quick adjustments and smooth transitions, making it an ideal choice for clients who handle a broad spectrum of U profile applications.

Integrated Hydraulic Punching for Efficient Production

One of the key technical highlights of the roll forming line is the hydraulic punching system, which is integrated directly into the main roll forming machine. This system allows for the punching of holes or notches on the profiles during the forming process, rather than as a separate step afterward. This integration not only reduces the overall production time but also ensures higher consistency and accuracy in every profile produced.

The hydraulic punching mechanism is controlled with high-precision sensors and programmable logic controls (PLC), offering automation and repeatability. Whether the punched holes are required for fixing, assembly, or ventilation, the machine ensures clean cuts and consistent positioning without deforming the profile.

Meeting the Demands of the Mexican Market

The Mexican market has shown a growing demand for roll formed steel products due to expansion in both infrastructure and commercial construction. The U profiles manufactured by this machine can be used in framing systems, partition supports, ceiling channels, and various other structural applications. The demand for customized profiles with pre-punched holes is also on the rise, as builders and fabricators seek ways to cut costs and improve installation speed on-site.

Our Mexican client, who has extensive experience in steel product distribution and manufacturing, selected this U profile roll forming machine after reviewing its specifications, videos of actual production, and feedback from previous users. They required a machine that could produce multiple U sizes and include hydraulic punching without the need for additional punching stations.

Careful Preparation and Loading

The process of preparing the machine for shipment involved a detailed inspection to ensure all systems were functioning correctly. After a final quality check and test run, the machine was carefully disassembled into modular parts suitable for container loading. Each component, including the main roll former, hydraulic unit, control cabinet, and safety guards, was securely packed with protective materials.

Our logistics team then loaded the components into a 20-foot container at the factory, taking all necessary precautions to prevent damage during transportation. The container was sealed and dispatched to Shanghai Port, where it will be shipped to Mexico via ocean freight.

Commitment to Global Service and Support

As part of our commitment to global customers, we will continue to support our client in Mexico through online guidance for machine installation, parameter setting, and operational training. If needed, our engineering team can provide in-person service to ensure smooth commissioning.

This shipment is another demonstration of our ability to serve international clients with tailored roll forming solutions. We take pride in designing machines that are not only technically advanced but also easy to operate and maintain.

With this machine soon to be operational in Mexico, we are confident it will contribute to the local industry by improving production efficiency and reducing manufacturing costs. We look forward to seeing our equipment make a lasting impact in yet another corner of the world.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria