-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Why 100/35 Roof Panels Are a Great Choice for Commercial and Industrial Buildings

Nov 14, 2024

Why 100/35 Roof Panels Are a Great Choice for Commercial and Industrial Buildings?

When it comes to choosing the right roofing material for commercial and industrial buildings, profiled metal panels like the 100/35 roof panel are a popular choice. These panels offer a range of benefits, from durability to ease of installation, making them ideal for businesses that need reliable and cost-effective roofing solutions. In this blog, we’ll dive into the advantages of 100/35 roof panels and why they are an excellent option for a variety of construction projects.

What Are 100/35 Roof Panels?

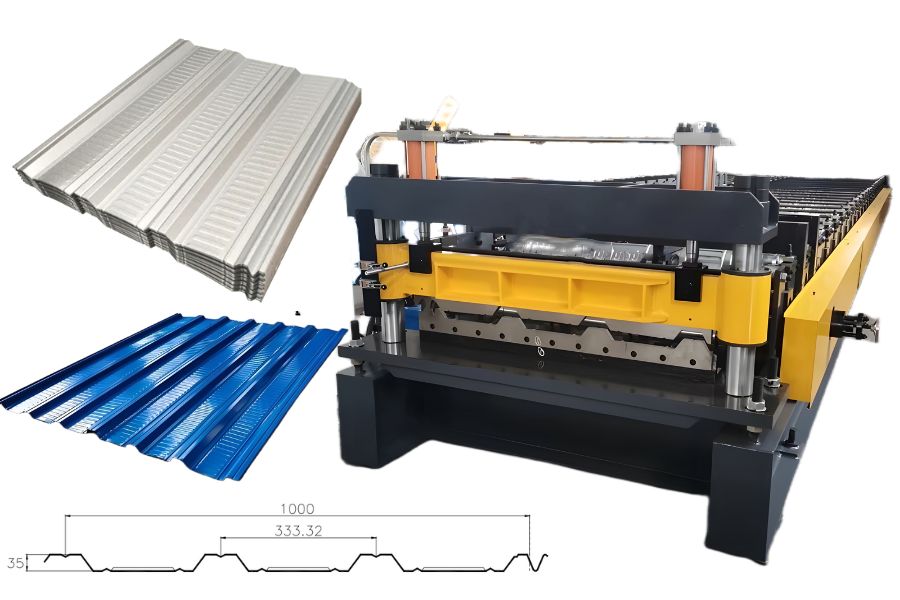

The term 100/35 roof panel refers to a profiled metal roofing panel with specific dimensions: 100 mm width between the ribs and 35 mm rib height. This design gives the panel strength and stability, making it ideal for both roofing and wall cladding applications.

The panel is typically made from galvanized steel or aluminum, both of which are known for their durability and corrosion resistance. The ribbed profile helps improve the panel’s load-bearing capacity and water runoff, making it an excellent choice for buildings exposed to the elements.

.jpg)

1. Structural Strength and Durability

One of the key features of 100/35 roof panels is their structural strength. The 35 mm rib height, combined with the 100 mm width between ribs, ensures that the panels are strong enough to withstand external forces such as wind, rain, and snow. This makes them ideal for industrial buildings, warehouses, factories, and other large structures that require a robust roofing system.

The metal materials used for the outer layers—typically galvanized steel or aluminum—are highly resistant to rust and corrosion. This makes the panels suitable for use in coastal or humid areas, where other roofing materials might degrade more quickly. The panels' durability ensures that they will continue to perform effectively for many years, even under harsh weather conditions.

2. Weather Resistance and Water Runoff

The 100/35 profile is designed to handle heavy rainfall and prevent water buildup on the roof. The corrugated design of the panels helps channel rainwater off the roof efficiently, reducing the risk of leaks or water damage. This is especially important in areas prone to heavy storms or extreme weather conditions.

Additionally, the weather-resistant properties of the metal panels provide long-lasting protection against corrosion and damage from the elements. The use of coatings such as Zinc-Aluminum (Zincalume) or Polyester further enhances the panel’s resistance to the effects of exposure to moisture and UV rays.

3. Cost-Effectiveness

When compared to other roofing materials, 100/35 roof panels are often more cost-effective in terms of both material cost and installation. These panels are pre-fabricated, meaning they arrive on-site ready to be installed, saving time and labor costs during the construction process. The ease of installation also means that the project can be completed more quickly, reducing downtime and increasing efficiency.

In the long term, the durability and low-maintenance nature of these panels make them a smart investment. With proper care, 100/35 roof panels can last for decades, reducing the need for frequent repairs or replacements.

4. Aesthetic and Design Flexibility

While 100/35 roof panels are primarily chosen for their performance, they also offer aesthetic flexibility. These panels come in a variety of colors and finishes, making it easy to match the roofing system to the building's overall design. Whether you’re building a modern commercial facility or a more traditional industrial building, there are options to suit every design preference.

The clean lines and corrugated profile of the 100/35 panel can also contribute to the building’s overall aesthetic, offering a sleek and professional appearance that enhances curb appeal.

5. Sustainability and Eco-Friendliness

Another important consideration for modern construction projects is sustainability. The 100/35 roof panel is often made from recyclable materials, such as galvanized steel, which can be reused at the end of its lifecycle. This reduces waste and minimizes the environmental impact of the roofing system.

Additionally, the energy efficiency of the panels can help reduce a building’s overall energy consumption by improving insulation and reducing heating and cooling costs. This makes 100/35 roof panels an eco-friendly option for those looking to create energy-efficient and sustainable buildings.

Application:

Conclusion

In conclusion, 100/35 roof panels are an excellent choice for commercial and industrial buildings due to their strength, durability, cost-effectiveness, and weather resistance. Their ability to handle heavy loads, provide efficient water runoff, and withstand harsh weather conditions make them ideal for a wide range

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria