-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

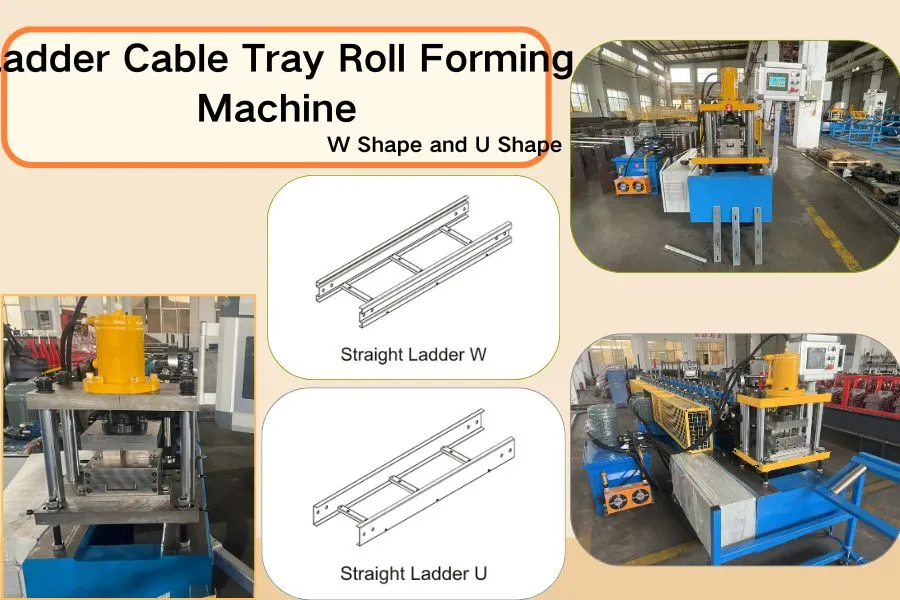

Advanced Applications of Ladder Cable Trays in Indonesia – W-Shape and U-Shape Solutions for Modern Infrastructure

Aug 06, 2025

Advanced Applications of Ladder Cable Trays in Indonesia – W-Shape and U-Shape Solutions for Modern Infrastructure

Introduction

As Indonesia accelerates its digital transformation and industrial growth, advanced cable management systems have become critical infrastructure components. W-shape and U-shape ladder cable trays are evolving beyond simple cable supports to become integrated solutions for smart factories, data centers, and renewable energy projects.

This technical blog examines:

✔ Innovative uses in Indonesian mega-projects

✔ Load calculation methodologies

✔ Custom fabrication techniques

✔ Maintenance strategies for maximum longevity

Cutting-Edge Applications

1. Smart Industrial Parks

-

W-shape trays with IoT sensor mounts

-

Integrated cable temperature monitoring

-

Fire-resistant coatings for critical areas

2. Hyperscale Data Centers

-

U-shape trays with EMI shielding

-

Overhead cooling integration

-

Modular designs for rapid deployment

3. Solar Power Plants

-

Galvalume-coated W-shape trays

-

UV-resistant cable management

-

Elevated designs for flood protection

Engineering Specifications

Indonesian Safety Factors:

-

Industrial: 1.5-2.0

-

Commercial: 1.2-1.5

-

Critical Infrastructure: 2.0-3.0

Span Capacity Comparison

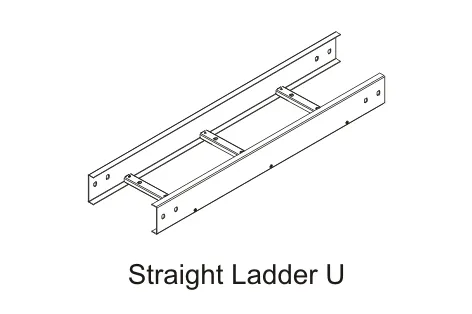

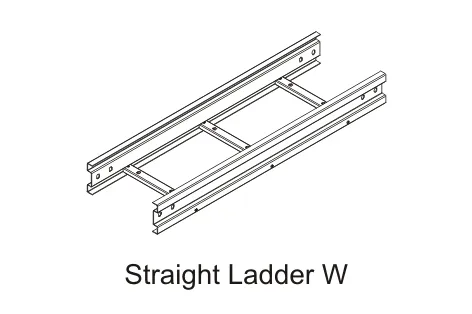

| Tray Type | 300mm Width | 600mm Width |

|---|---|---|

| W-shape | 150kg/m @ 3m | 300kg/m @ 3m |

| U-shape | 100kg/m @ 2.5m | 200kg/m @ 2.5m |

Custom Fabrication Techniques

1. Specialized Coatings

-

Zinc-aluminum coatings for aggressive environments

-

Epoxy paints for chemical plants

2. Modular Connections

-

Flanged joints for seismic zones

-

Quick-release fittings for maintenance

3. Hybrid Systems

-

W-shape main runs with U-shape branches

-

Composite material sections

Maintenance Protocols

Annual Inspection Checklist

-

Coating integrity: Check for rust spots

-

Fastener tightness: Re-torque all bolts

-

Alignment: Verify ≤3mm deviation per 10m

-

Load verification: Confirm no overloading

5-Year Major Maintenance

-

Ultrasonic thickness testing

-

Structural reinforcement assessment

-

Complete recoating if needed

Case Study: Jakarta MRT Project

Challenge:

-

High-density cable routing

-

Vibration resistance requirements

-

Flood zone installation

Solution:

-

Custom W-shape stainless steel trays

-

Vibration isolators every 5m

-

Elevated mounting brackets

Results:

✔ 40% faster installation than conventional methods

✔ Zero maintenance issues after 3 years

✔ Complied with PUIL 2011 electrical standards

Future Trends

-

Smart trays with embedded power/data

-

Lightweight composites for earthquake resilience

-

Robotic installation systems

Conclusion

Indonesia's infrastructure boom demands high-performance cable tray systems that combine traditional reliability with modern innovations. Whether specifying W-shape for industrial toughness or U-shape for commercial flexibility, understanding advanced applications ensures optimal project outcomes.

If you are interested in the W shape and U Shape Ladder Cable Tray, please contact us..webp)

.webp)

.webp)

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria