-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

How to produce high grade corrugated sheet?

Jul 21, 2025

How to produce high grade corrugated sheet?

We have two methods to produce corrugated iron sheet, one is made by roll forming machine; other one is made by barrel type corruagetd sheet machine

Here’s a step-by-step guide for producing metal corrugated sheets, which are commonly used in roofing and wall cladding:

A:Roll Forming Machine Production Process

1. Raw Material Preparation

-

Material: Galvanized steel coils or other pre-painted steel.

-

Thickness: Usually between 0.2 mm to 1.2 mm, depending on application.

-

Width: Depends on the finished profile width (typically 762mm, 914mm, or 1000mm effective cover).

2. Decoiling

-

The steel coil is loaded onto a decoiler.

-

The decoiler unwinds the coil and feeds it into the machine.

3. Feeding & Guiding

-

The sheet passes through guiding rollers to ensure it's straight and properly aligned.

-

A pinch roller or feeder pulls the material into the forming section.

4. Roll Forming

-

The core process happens in the roll forming machine.

-

Multiple rollers gradually shape ( about 23 rollers) the flat sheet into a corrugated profile.

5. Cutting

-

A hydraulic or fly-cut shear cuts the sheet to the desired length.

-

Cutting is usually synchronized with the forming speed.

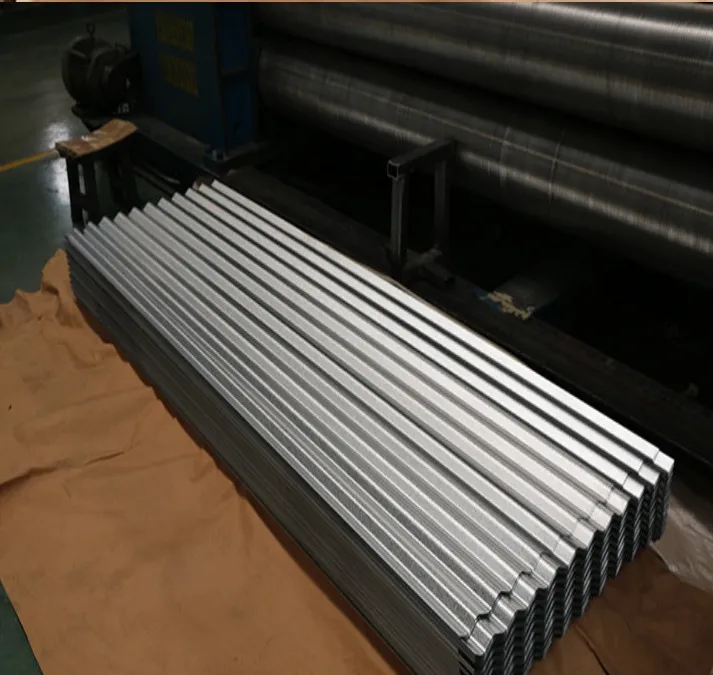

6. Output & Stacking

-

The finished corrugated sheets exit the machine.

-

They are manually or automatically stacked for packing.

.webp)

.webp)

B: Barrel Type Corrugated Machine Production Process

You need to purchase the sheets length like (3 meters or 4 meters) you want to produce, then the worker take the sheets into barrel type machine, one time can produce 3 sheets or 4 sheets, it is manually one, low speed.

If you want high-speed production(e.g., 10–15m/min vs. high-speed 30m/min lines), choose the molding machine solution; if you want to save costs, please choose the barrel type.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria