-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Growing Demand for Servo Following Strut Channel Roll Forming Machines: A Versatile Solution for All Types of Metal Fabricators

May 21, 2025

In response to increasing market demands and evolving customer requirements, our factory has recently completed the production of multiple servo following strut channel roll forming machines. With a design philosophy rooted in precision, flexibility, and high efficiency, this production line has quickly become an ideal solution for enterprises of all sizes in the strut channel industry — from small workshops to large-scale metal fabrication facilities.

Tailored for Diverse Needs

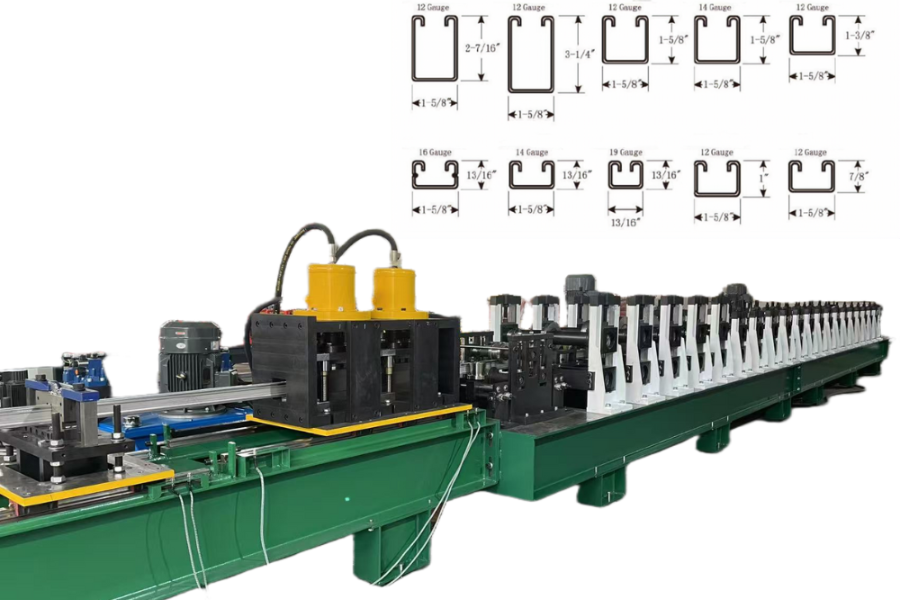

What makes this machine line stand out is its remarkable adaptability. While the standard profiles it produces include 41×21mm, 41×41mm, 41×52mm, 41×62mm, 41×72mm, and 41×82mm, with material thicknesses ranging from 1.5mm to 2.5mm, the system is also fully customizable. Whether customers require special dimensions or materials, such as galvanized steel or stainless steel, our engineering team can deliver tailored solutions to meet those exact needs.

The ability to handle both standard and custom profiles has made this production line a popular choice among customers from various sectors, including electrical infrastructure, construction, HVAC support systems, and industrial shelving.

Innovative Technology for Next-Level Performance

A key highlight of this production line is its servo following punching and cutting technology, which replaces the need for large and expensive mechanical presses. This not only reduces the overall footprint of the equipment but also improves accuracy and operational efficiency.

The servo following hydraulic punching unit ensures synchronized and precise punching even when the machine is operating at full speed. Immediately after punching, the servo tracking shear performs the cut-to-length action without halting the production line, supporting a maximum production speed of up to 10 meters per minute. This configuration eliminates unnecessary stops and minimizes material waste.

Compact and Streamlined Layout

Despite its powerful capabilities, the full production line is compact, occupying only about 25 meters in length. The thoughtful layout contributes to space-saving in the workshop and makes it easier for operators to manage the workflow. Furthermore, the streamlined design enhances machine accessibility for maintenance and tooling changes.

Easy Tooling Change – Spacer or Cassette Option

Tool changeover has been engineered with convenience in mind. For changing the profile height, most customers choose to replace spacers, a method that is cost-effective and simple. This process takes a short time and does not require dismantling major components, making it suitable for small and medium-sized production facilities.

For customers with higher budgets or those requiring frequent profile changes, we offer the option to install cassette-type tooling systems. These modular cassettes allow for quick changeovers between different profile heights, drastically reducing downtime and improving production flexibility. Operators can swap out the entire cassette within minutes, enabling them to shift between production orders with ease.

Applications and Industry Relevance

Strut channels are widely used across many industries for mounting, supporting, and connecting lightweight structural loads. Common applications include:

-

Electrical cable tray systems

-

Pipe and conduit support

-

HVAC duct mounting

-

Equipment frame construction

-

Warehouse shelving systems

With growing infrastructure development and modular construction practices across the globe, the need for reliable and adaptable strut channel manufacturing equipment is stronger than ever. Our servo following strut channel roll forming machine answers that call with superior design and engineering.

Custom Engineering and Support

Every machine shipped from our facility is backed by comprehensive technical support, training, and, if needed, on-site commissioning. We work closely with clients to understand their exact requirements before customizing the machine to suit their production goals.

Our team believes that one size doesn't fit all — and this philosophy has helped us win the trust of both domestic and international clients in recent years. Whether a company is launching its first metalworking line or expanding its factory operations, our production line can seamlessly integrate into their workflow.

Looking Ahead

As more customers shift toward automated and flexible production methods, servo following roll forming technology will continue to play a leading role in shaping the future of strut channel manufacturing. With each machine we deliver, we aim to empower our clients with solutions that increase productivity, reduce labor intensity, and elevate quality standards.

Our factory is proud to be at the forefront of this evolution, delivering machinery that not only meets industry standards but sets new ones.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria