-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Light Steel Frame Machine vs. Floor Joist Machine

May 26, 2025

1. Light Steel Frame Machine

A light steel frame machine is a specialized roll-forming system that produces cold-formed steel (CFS) components for modern construction. These machines transform galvanized steel coils into precise framing elements used in walls, ceilings, floors, and roof systems.

Material Input: Galvanized steel coils (0.8mm–1.2mm thickness or 0.8-2.0mm).

Profiles sizes: C63, C75, C89, C100, C152, C200 and custom shapes, which can do single size steel fame machine or multuple sizes steel frame machine.

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

Key Advantages:

Fast production of standardized framing components.

Adjustable for different sizes (e.g., 63mm–200mm stud depth).

Suitable for drywall, modular housing, and prefab construction.

Limitations: Not designed for heavy structural load-bearing parts.

Applications

✅ Drywall framing (residential/commercial interiors)

✅ Suspended ceiling systems

✅ Prefabricated steel partition walls

2. Floor Joist Machine

Definition & Features

A floor joist machine manufactures load-bearing steel joists used in floors, roofs, and mezzanines. These machines produce thicker, high-strength C or I-shaped profiles to support heavy loads.

-

Material Input: High-strength steel coils (2.0mm–3.0mm thickness).

-

Profiles sizes: C-joists with C200, C250 and C305

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

.jpg?x-oss-process=image/resize,w_100/quality,q_100)

-

Key Advantages:

-

High load capacity (ideal for long spans).

-

Fire-resistant and termite-proof vs. wood joists.

-

Used in residential, commercial, and industrial projects.

-

-

Limitations: Higher material cost than wood; requires precise engineering.

Applications

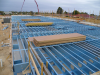

✅ Residential/commercial flooring systems

✅ Loft and mezzanine structures

✅ Prefabricated steel-framed buildings

3. Key Differences

| Feature | Light Steel Frame Machine | Floor Joist Machine |

|---|---|---|

| Primary Use | Non-load-bearing framing | Structural load-bearing joists |

| Profile Thickness | 0.5mm–2.0mm | 1.2mm–3.0mm+ |

| Output Shapes | C-stud, U-track | C-joist |

| Strength | Low to medium (partition walls) | High (floor/roof support) |

| Span Capacity | Short spans (≤4m) | Long spans (6m–12m+) |

| End Products | Drywall studs, ceiling frames | Floor joists, roof trusses |

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria