-

tel:

+86-13606193016 -

email:

info@suhangmachine.com

Roof Trim with Different Types & Their Function

Jun 23, 2025

Roof trim, also known as roof edging, refers to the various materials used to cover and protect a roof's edges, intersections, and transitions. It creates a watertight seal and a flawless appearance on the surrounding surface of chimneys, skylights, and other roof penetrations. It also adds a polished finish to your roof and defines the edges of your home.

What Is The Role of Roof Trim?

Roof trim acts as additional protection for your roof, as it prevents moisture and debris from entering your home. It also helps safeguard the underlying roof structure from water damage, rot, and deterioration by creating a barrier against moisture intrusion at vulnerable points.

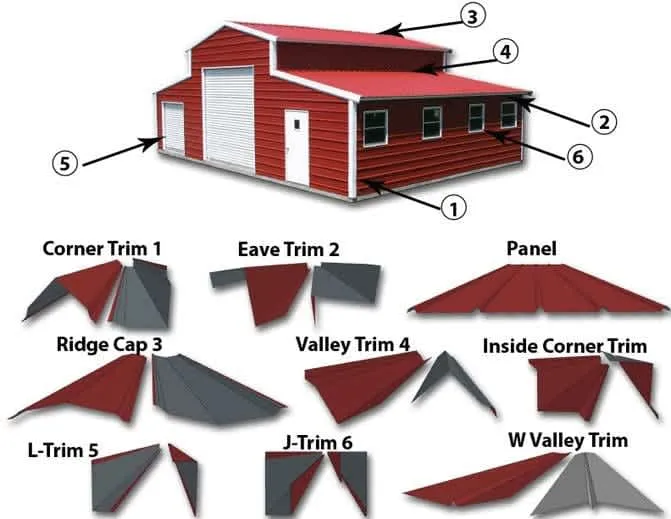

Here are some common types of roof trims:

1. Drip Edge

-

Installed along the eaves and rakes of the roof.

-

Directs water away from the fascia and into the gutter.

-

Prevents water from seeping under the roofing material.

2. Ridge Cap

-

Covers the peak (ridge) of the roof where two slopes meet.

-

Provides a waterproof seal and enhances ventilation in some designs.

-

Available in various materials (metal, shingle, etc.) to match the roof.

3. Gable Trim (Rake Edge Trim)

-

Used along the sloping edges (rakes) of a gable roof.

-

Protects the roof deck from wind-driven rain and pests.

-

Often made of aluminum or steel for durability.

4. Fascia Trim

-

Covers the fascia board (the vertical edge of the roof).

-

Supports the bottom row of shingles and gutters.

-

Helps prevent moisture damage and rot.

5. Valley Flashing

-

Installed in roof valleys (where two roof planes intersect).

-

Channels water away to prevent leaks.

-

Typically made of galvanized steel, aluminum, or copper.

6. Corner Trim

-

Used at roof corners for a clean, finished look.

-

Protects edges from weather and adds structural reinforcement.

7. Soffit Trim

-

Covers the underside of the roof overhang (soffit).

-

Enhances ventilation and prevents pests from entering.

-

Often perforated to allow airflow.

Materials Used for Roof Trims:

-

Aluminum: Lightweight, rust-resistant, and easy to install.

-

Galvanized Steel: Strong and durable, often coated for extra protection.

-

Copper: Long-lasting and develops a patina over time (high-end option).

-

Vinyl: Affordable and low-maintenance but less durable than metal.

Installation Tips:

-

Ensure proper overlap to prevent water infiltration.

-

Use corrosion-resistant nails or screws.

-

Seal joints with roofing cement or flashing tape if needed.

-

Follow manufacturer guidelines for best performance.

One machine can help you of different roof trims, we called it CNC fold machine.

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

.webp?x-oss-process=image/resize,w_100/quality,q_100)

A CNC folding machine (also called a CNC press brake) is an advanced tool used to fabricate precise and complex roof trim profiles from sheet metal. These machines automate the bending process, ensuring high accuracy, repeatability, and efficiency—ideal for producing drip edges, fascia trims, ridge caps, and other roofing components.

How a CNC Folding Machine Works for Roof Trims

-

Material Loading

-

Sheet metal (aluminum, galvanized steel, copper) is fed into the machine.

-

Common thickness: 0.5mm to 1.0mm (depends on trim type).

-

-

CNC Programming

-

The operator inputs bend angles, lengths, and sequences using CAD/CAM software.

-

Example: A drip edge profile may require a 90° bend + a small lip (10-15°).

-

-

Automated Bending

-

Hydraulic or electric press brakes apply force to fold the metal along programmed lines.

-

Back gauges ensure consistent positioning for multiple bends.

-

-

Output

-

Finished roof trims are cut to length, deburred, and ready for installation.

-

CNC is a manually operated device. If you want to improve work efficiency, we can also provide you with roll forming machine solutions, Sussman Machinery can customized the machines as your request.

Please contact us for more information.

Related News

October 26, 2016

The Most Successful Engineering Contractor

Sep 19, 2025

Upright Rack Roll Forming Machine Shipped to Algeria